Welding Process : A Joining Process

Introduction To Welding:

- Welding is a fabrication process to produce permanent joints between two similar and dissimilar materials, with or without the application of heat and pressure.

- For example – Arc welding and gas welding : Only heat.

- Function welding and resistance welding : Both heat and pressure

- Explosion welding : Only pressure

Fundamentals of Arc Welding

1.Principle of Arc Welding :

To generate the arc, at first a contact is made between electrode and workpiece due to which partial melting and evaporation occurs at the interface and the two ends are severely heated due to which the electrons and ions at both the ends become electrically unstable.

As soon the contact is disengaged and small gap is maintained between the electrode and workpiece than at first the positively unstable ions emit from positive side and move towards the negative side to gain the stability.

Due to this ionic emission the gap between electrode and workpiece is ionized and through this ionized medium the unstable is travel towards positive side within the envelope of positive ions moving in opposite direction.

Those electrons and ions which are at the interface collide with each other and their kinetic energies convert into intense ultraviolet radiation and the arc heat.

Rest of the electrons and ions bombard at the positive and negative sides respectively where their kinetic energies convert into heat energy.

Since the kinetic energy of electron is more than that of ions therefore, larger amount of heat (about 2/3rd.) is developed at the positive side where the electrons bombard and relatively lesser amount of heat ( 1/3rd.) is developed at negative side where the ions bombard.

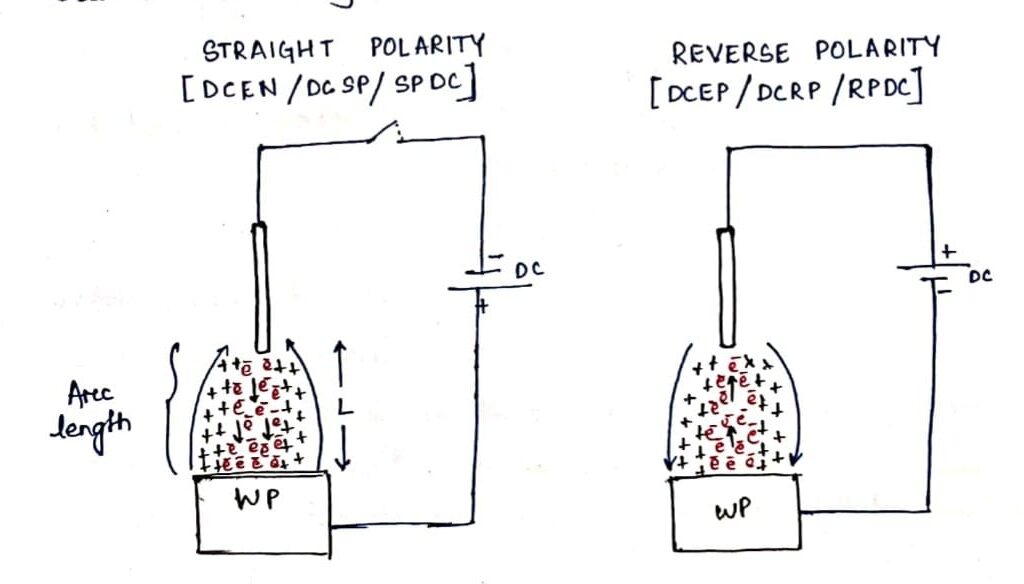

With direct current source if the workpiece is made positive and the electrode negative then it is called as straight positive and if the electrode is made positive and workpiece negative then it is called as reverse polarity.

This phenomena of arc generation is called as thermionic emission arc length can be sustained depends totally upon the arc voltage i.e voltage of power source must be a function of arc length and it must vary linearly with the arc length. In most of the welding process the arc voltage is limited upto 80V for the welders safety.

The Required Arc Current Depends on the Following Factors :

- Type of material

- Type of joint

- Type of electrode

- Diameter of electrode

- Type of coating over the electrode

- Thickness of the weldment

- Position of the weld

The Required are Current Varies Linearly with the Electrode Diameter :

I=Kd

where, k = constant

- The standard are length should be equal to the diameter of electrode while the standard width of the weld bead is three times the diameter of electrode.

Types of Electrodes :

- Non Consumable Electrode

- It is made up of high melting point materials such as tungsten and graphite which is only used to generate the arc and to keep the arc stable. Since the non-consumable electrodes do not melt therefore the arc is more stable and easier to be maintained. But the deposition rate with NC electrode will be nill and hence it will not provide any filler material.

- Consumable Electrodes.

These electrodes melt during welding and hence provide filler metal and are made up of same material being welded until alloying is required.

These are of 2 types-

- Bare electrode:

These electrodes are either in form of wire or Rod. Wire type electrodes are in form of a spool of a wire and are used in semi-automatic and automatic arc welding.

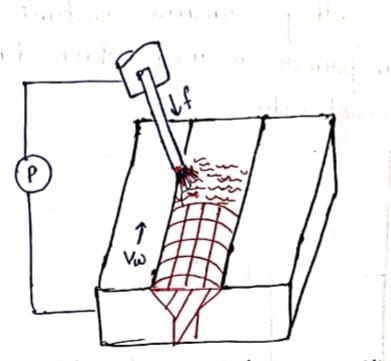

During welding the electrode holder has following two movements.

•The electrode holder needs to be fed towards the pool, with the same rate with which it is being consumed.

•The movement of electrode holder along the length of weldment.

If both of above movements are controlled manually then it is called as manual arc welding but if the first movement is controlled automatically and second manually then it is called as semi-automatic arc welding and if both of the above movements are controlled automatically then it is called as automatic arc welding.

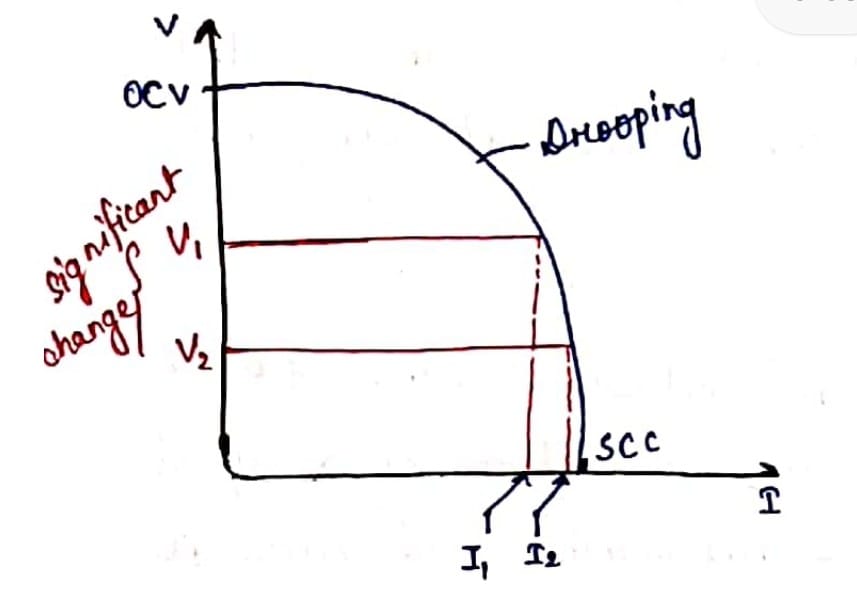

In case of manual are welding it is impossible to keep the arc length constant. Therefore the arc length will keep changing, to keep the power input constant into the weld region the current being with drawn into the arc will also have to change. Therefore, in manual arc welding we use a constant Current transformer which has a drooping volt ampere characteristic because its secondary winding is made movable.

It can be observed that for a significant change in voltage there is in significant change in current to keep the роwer constant and therefore it is named as constant current transformer.

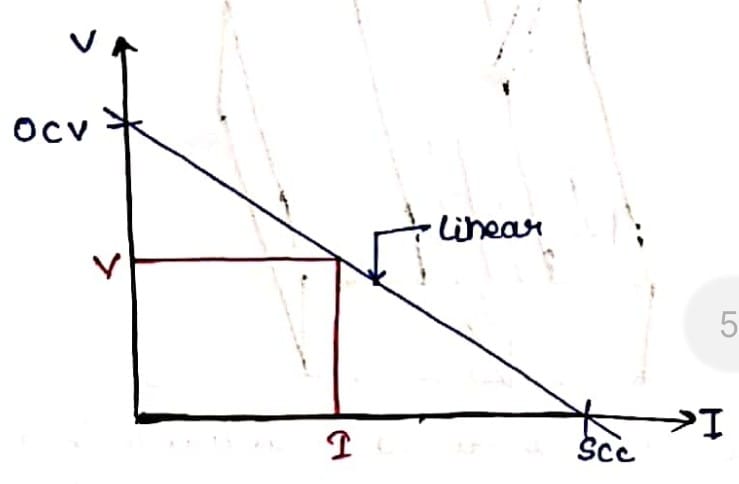

- In semi-automatic and automatic arc welding since feeding is done automatically therefore the arc length and hence the arc voltage remains constant and hence a constant voltage transformer is used which has a linear volt ampere characteristic.

The VI line can be shifted up and down and its slope can be change by changing the OCV and sec to have different power characteristic

For Stable Arc:

- In constant voltage transformer

V Arc =V Transformer

- In constant current transformer.

L Arc = L Transformer

The linear volt-ampere characteristic constant voltage transformer in semi-automatic and automatic arc welding is given as follows:

V = OC V – [OCV/SSC]

Where,

OCV: Open Circuit Voltage: maximum voltage in circuit :

SCC: Short Circuit Current: Maximum current in circuit

Ohm’s law is invalid

Note: For a constant power (P-VI) voltage is inversely proportional to current and as we know from voltage arc length characteristic that arc length is directly proportional to arc -length. Therefore, arc currant will be inversely proportional to arc length.

Red type consumable electrode which arc bare are used in manual arc welding.

Coated Electrode:

- Coated electrodes have a coated over the electrode wire which has following seating characteristics.

- It provide protective shielding.

- It stabilizes the arc It provide protective slag coating to accumulate impurities, prevent oxidation, slows down the cooling rate and hence produce strong and uniform green weldments.

- It minimizes the effects of arc blow.

- It reduces a spatter losses.

- It may add elements.

- It may add additional filler material.

Ingredients of Electrode Coating

Slag forming ingredients:

- Asbestos, mica, Silica, Fluorspar, titanium dioxide, Aluminiumoxide, Calcium carbonate, magnesium carbonate

Arc Stabilizing Ingredients/Ionizing Ingredients :

Potassium Silicate, Sodium Silicate, Calcium Oxide, Sodium Oxide, Feldspar, Rutile (TiO₂ + ZnO₂).

Deoxidizing Ingredient:

Cellulose, starch, Dex trine, Saw dust, Dolomite, Aluminum.

Binding ingredient:

Sodium silicate and potassium silicate.

In AC arc welding the electrodes with potassium silicate binder is preferred because ionization potential of potassium is less then that of sodium.

TIM

Note: Ionization potential is the potent energy required to emit an e a neutral atom.

Arc Blow :

Are blow occurs due to unbalanced magnetic forces. While welding. the centre f near the workpiece the no. of magnetic line of forcer. sider of on the two the are will be approximately same and hence the are will not deflect but during welding near the corners or edges. the concentration of magnetic lines of forces will be maximum at one side. Therefore, the are will deflect and this phenomenon is called as are blow

- The are blew and its effect will be severe if the рошем Source is DC and electrode is bare type and the material is. highly magnetic such as Nickel. alloy…

- Laser Beam Machining(LBM)

- Automation And Types of Automation in Manufacturing

- Numerical Control(NC) and Computer Numerical Control(CNC)

- Plasma Arc Machining(PAM)

- Heat Engine, Classification of Heat Engine and Its Component

Hi!

Take control of your financial future with binary options trading on our platform. Start with a small investment of just $10 and watch your profits soar. Our platform offers market analysis, a user-friendly interface, and secure transactions. With 24/7 access, you can trade from anywhere, at any time. Start your journey to financial freedom today.

Earn every minute without limit of $100, $500, $1,000, with a minimum bet of $1.

Instant withdrawal!!!

WARNING! If you are trying to access the site from the following countries, you need to enable VPN which does not apply to the following countries!

Australia, Canada, USA, Japan, UK, EU (all countries), Israel, Russia, Iran, Iraq, Korea, Central African Republic, Congo, Cote d’Ivoire, Eritrea, Ethiopia, Lebanon, Liberia, Libya, Mali, Mauritius, Myanmar, New Zealand, Saint Vincent and the Grenadines, Somalia, Sudan, Syria, Vanuatu, Yemen, Zimbabwe.

Sign up and start earning from the first minute!

https://trkmad.com/101773

I appreciate, cause I found just what I was looking for. You have ended my four day long hunt! God Bless you man. Have a great day. Bye

Custom Stamp Maker

create your own stamp https://www.stamp-maker.us/.

Дома каркасные: современный дизайн с экономичностью

каркасные дома https://www.karkasnye-doma-pod-klyuch78.ru/.

Отличный ассортимент грилей газовых

купить газовый гриль барбекю https://www.bbbqqq11.ru/.

Профессиональные похоронные ритуалы

ритуальные услуги кремация ritual-gratek11.ru.

Доставка цветов до двери в любую точку мира

купить цветы в москве недорого http://dostavka-cvetov77.ru/.

Автокредит – проценты от 0%

автомобиль в кредит http://www.tb-avtokredit1.ru.

Почему двигатель Cummins – лучший выбор?

дизельный двигатель для спецтехники двигатели-для-спецтехники.рф.

Льготы по НДФЛ

подоходный налог с зарплаты tb-ndfl1.ru.

Виды УСН для самозанятых

упрощенная система налогообложения в 2023 году для ооо http://www.tb-usn1.ru.

Прекрасные туры по странам

тур в дагестан https://www.tours-eks.ru/tours/region/dagestan.

Налог на добавленную стоимость: успех в налоговой регистрации

уплата ндс https://www.tb-nds1.ru.

Надежное бурение и ремонт скважин

ремонт скважин на воду https://www.voda-narodu11.ru/.

Производственный календарь на 2023 год при 5-дневной рабочей неделе

праздничные дни в январе tb-proizvodstvennyj-kalendar-2023-1.ru.

Особенности дебетовой карты для бизнеса

лучшие дебетовые карты http://tb-debetovaya-karta1.ru/.

Типы и функции кредитных карт

кредитные карты банков https://www.tb-kreditnaya-karta1.ru/.

Что значит льготная ипотека и кому она предоставляется?

льготная ипотека банки tb-lgotnaya-ipoteka1.ru.

Подарите себе новую квартиру в Лимассоле на лето

квартира в лимассоле снять kvartira-v-limassole.ru.

Онлайн клинкерная плитка: цены и характеристики

клинкерная плитка для фасадов http://www.klinkerprom11.ru/.

Где в Москве можно купить доллары?

курс доллара в обменниках москвы на сегодня http://www.tb-kupitb-dollar1.ru.

Как открыть ИП в России?

регистрация ип в москве https://tb-otkrytb-ip1.ru.

Открываем ООО – подготовка и регистрация юридического лица

ооо как открыть https://www.tb-otkrytb-ooo1.ru/.

Выгодные билеты на самолет

aviabilet http://www.tb-kupitb-biletb-na-samolet1.ru/.

Зачем нужно каско страхование автомобиля

расчет каско от угона онлайн https://www.tb-kasko1.ru/.

Оформление ипотеки: пошаговое руководство

кредиты на квартиру https://tb-ipoteka1.ru/.

Какие документы нужны для страхования ипотеки

выгодно страхование ипотеки tb-strahovanie-ipoteki1.ru.

Купить туристическую страховку ВЗР онлайн, рассчитать стоимость

страхование путешествий https://www.tb-vzr1.ru.

eSIM и безопасность данных: стоит ли беспокоиться?

esim операторы https://tb-esim1.ru.

Биржевые индексы: как они влияют на инвестиции

что такое инвестиции и как начать инвестировать https://www.tb-investlab1.ru.

Уборка после мероприятий и праздников

мытье окон в москве klining-moskva-77.ru/moika-okon.

Никакого риска: получите безупречный перевод с английского языка

технический перевод онлайн https://www.b2bperevod11.ru/.

Услуги уборки домов и квартир: комплексный подход к чистоте

генеральная уборка http://klining-spb-78.ru/uborka-kvartir/generalnaya-uborka-kvartir/.

Где купить паракорд по доступной цене?

паракорд купить в москве недорого https://parakord77.ru.

Секреты успеха облачных касс: как выбрать лучшую для своего бизнеса

купить облачную кассу для интернет магазина https://www.oblachnaya-kassa-arenda.ru.

Улучшите свою кредитную историю с помощью наших займов без справок

Моментальные займы онлайн topruscredit11.ru.

Оптовая и розничная продажа металлопроката от производителя

цена арматуры краснодар http://www.armatura-krd.ru.

Роль допуска СРО для строительной отрасли: что нужно знать?

сайт сро реестра https://sroforum.ru.

Выбор поставщиков технического аргона: ключевые факторы и рекомендации

баллон аргон https://www.tekhnicheskie-gazy.ru.

Надежные и функциональные домофоны и видеонаблюдение по выгодным ценам

система видеонаблюдения купить https://www.evroks.ru.

Профессиональная защитная одежда: стиль, безопасность и функциональность в одном

спецодежда сайт https://spetsodezhda-tambov.ru.

Разработка и продвижение сайтов под ключ

создание сайтов на заказ s-e-o-paul.ru.

Комплексное обеспечение безопасности на вашем предприятии – от разработки знаков до обучения персонала

плакаты электробезопасности https://ets-diesel.ru.

Рихтовка и восстановление кузова авто

покраска авто в краснодаре https://www.avtoremont18.ru/.

Доступное строительство ангаров и магазинов под ключ

ангар из металлоконструкций https://bystrovozvodimye-zdaniya-krasnoyarsk1.ru/.

Реабилитация для здоровья: преимущества и результаты

реабилитация людей http://www.медицинская-реабилитация.москва.

Время для оформления полиса ОСАГО: когда лучше это сделать

осаго в москве http://www.tb-osago1.ru.

Преимущества использования облачных касс

аренда облачной кассы http://www.oblachnaya-kassa-arenda.ru/.

Вместительные мешки для мусора по выгодным ценам

мешок для мусора meshki-dlya-musora-mmm.ru.

Услуги ветеринарной клиники: от диагностики до лечения на дому

стерилизация кошек цена veterinary-clinic-moscow2.ru.

PRIVATE TRANSACTION

I propose a partnership to manage over invoice petroleum oil and gas strategic reserve resources. Please response for fund credentials and detailed information to: joneseloff.mr@hotmail.com

We look forward to the opportunity to work together and create a mutual beneficial partnership.

Thank you

Regards

Jones Eloff

Играйте в казино Риобет сегодня

риобет зеркало http://www.riobetcasino.ru.

Быстрое строительство быстровозводимых объектов в любых условиях

строительство вахтовых поселков https://www.bystrovozvodimye-zdaniya-krasnoyarsk1.ru/.

Экологичные мешки для мусора по лучшим ценам

мешки мусорные http://meshki-dlya-musoramsk.ru/.

Прекрасные ароматы духов для людей со вкусом

описание аромата женских духов http://montalefragrance.ru/.

Мешки для разных видов мусора: огромный выбор и выгодные условия покупки

мешок для мусора http://www.meshki-dlya-musoraru.ru.

Оптимизируйте работу с персоналом с 1C УНФ

1с фреш управление нашей фирмой https://www.426clouds.ru/.

Курсы SEO: Мониторинг и определение эффективных стратегий раскрутки сайта

обучение seo продвижению https://seo111.ru.

Ingco – инструменты, которые превзойдут ваши ожидания

ingco ingco-instrument213.ru.

Мы помогаем найти идеальную сиделку для ваших близких

найти сиделку в калининграде https://www.sidelki39.ru/.

Украсьте свой дом с рулонными шторами, созданными специально для вас

рулонные шторы блэкаут с электроприводом http://www.prokarniz13.ru/.

Современные пневмоцилиндры для повышения эффективности вашего производства

пневмоцилиндры http://www.pnevmolab.ru.

Гибкие условия оплаты и доставки автомобильных весов

весы автомобильные электронные http://baltvesy.ru/.

Любимые модели коллекции одежды для новорожденных

одежда на выписку для новорожденных http://mama-kenguru.ru/.

SEO курсы: Введение в SEO-продвижение, раскройте потенциал вашего сайта

курсы по seo продвижению http://www.seo-fl.ru.

Строительные леса по доступной цене

аренда сцены для мероприятий http://www.arenda-stroitelnyih-lesov1.ru/.

Верните себе здоровье с помощью клиники остеопатии

клиника остеопатии в москве http://www.osteopatclinic.ru/.

Обзор популярных услуг салона красоты Новосибирска: от эпиляции до маникюра

карбамидный педикюр https://www.salon-krasotyi-novosibirsk1.ru/.

Как выбрать юриста для бесплатной юридической консультации

задать вопрос юристу http://www.xn—-12-53dl8bl9bomm8b5a5g.xn--p1ai/.

Пластиковые окна нестандартной формы и размера на заказ

окна рехау купить http://www.plastokoshko.ru/.

Популярные бренды и производители электроники в интернет магазине ДНР

интернет магазин электроники днр http://internet-magazin-elektroniki-dnr.ru/.

Как правильно подобрать строительные леса для аренды

аренда сцены для мероприятий https://www.arenda-stroitelnyih-lesov1.ru.

Корпоративные сувениры: зачем они нужны и как выбрать подарок

подарки челябинск https://www.suveniry-i-podarki11.ru/.

Explore the Mystake Casino’s Game Variety

my stake casino review http://www.vpesports11.com/.

Системы безопасности: видеонаблюдение и домофоны в Краснодаре для вашего дома и бизнеса

сервер для скуд evroks.ru.

Профессиональные услуги салона красоты в Новосибирске

депиляция интимной зоны salon-krasotyi-novosibirsk1.ru.

Как продвинуть сайт на первые места в поисковиках

веб сайт создание краснодар https://www.s-e-o-paul.ru/.

Недвижимость в Фамагусте – Купить Дом в Фамагусте

купить дом в фамагусте http://dom-v-famaguste.ru/.

Доставка и покупка металлопроката в Краснодаре: наши условия

арматура купить http://www.armatura-krd.ru.

Роскошные квартиры в Пафосе с видом на Средиземное море

аренда квартиры в пафосе https://www.kvartiry-v-pafose.ru/.

Документы для получения визы во Францию из Москвы

получить визу во францию в москве 2023 visa-vo-franciyu-moskva.ru.

Как оформить визу в США в Москве

виза в сша сделать в москве visa-usa-moskva.ru.

Сколько стоит получить визу в Италию в Москве

оформить визу в италию в москве http://visa-v-italiyu-moskva.ru/.

Срок действия визы Испании из Москвы и сколько стоит виза

шенгенская виза в испанию в москве https://visa-v-ispaniyu-moskva.ru.

Печать фирменных бланков и конвертов в типографии

Московская типография полного цикла http://envelope-print.ru/.

Как правильно получить бизнес визу в Китай в Москве

срочно виза в китай оформить москве http://www.visa-v-kitaj-moskva.ru/.

Продвижение сайтов: лучшие стратегии

заказать seo продвижение https://prodvizhenie-sajta.by.

Продвижение сайта для привлечения клиентов

продвижение сайтов в сша европе https://prodvizhenie-sajtov11.ru.

Недорогие квартиры для покупки в Фамагусте: экономичные решения для жизни

купить квартиру в фамагусте https://kupit-kvartiru-v-famaguste.ru/.

Использование мягкого бластинга в клининговых услугах

мягкий бластинг myagkii-blasting.ru.

Сантехнические работы на дому – быстрый ремонт и устранение протечек

сантехник услуги https://santekhnik-na-dom01.ru.

Как просто и эффективно провести уборку после смерти человека

уборка квартиры после смерти цена uborka-posle-smerty.ru.

Вызвать сантехника на дом: рекомендации и отзывы

сантехник вызвать http://www.vyzov-santekhnika-spb.ru.

Борьба с вредными микробами: дезинфекция помещения

дезинфекция помещений магазина http://dezinfekciya-pomeschenii.ru/.

Сколько стоит уборка после затопления канализацией

уборка после затопления канализацией https://www.uborka-posle-zatopleniya-kanalizaciei.ru.

Эффективное устранение неприятных запахов в салоне автомобиля с помощью озонирования

устранение запахов озоном москва https://ozonirovanie-pomeschenii.ru/.

Уборка квартиры после потопа: профессиональный подход к решению проблемы

уборка после затопления домов http://www.uborka-posle-potopa.ru.

Сантехнические услуги: как найти хорошего мастера

вызов сантехника на дом спб https://www.uslugi-santekhnika01.ru/.

Прайс лист на услуги клининговой компании по уборке запущенных квартир

уборка захламленных и запущенных квартир uborka-zapuschennih-kvartir.ru.

Лучшие способы уничтожения плесени в квартире

обработка от плесени https://www.obrabotka-ot-pleseni.ru/.

Быстрое и безопасное удаление неприятных запахов в квартире с помощью дезодораци

удаление запахов в квартире сухим туманом https://dezodoraciya-kvartiri.ru/.

Кремация человека в Москве: правила и стоимость

кремация в москве цены https://www.ritual-gratek13.ru/.

Лучшие двигатели для спецтехники – официальный поставщик

двигатель cummins евро 5 http://www.xn—–6kchfeegdazdfa3aid3b9a2bnk4eva4t.xn--p1ai.

Базовый курс перманентного макияжа с сертификатом: практическое обучение

курсы перманентного макияжа цена https://www.unopmu11.ru/.

Успешное трудоустройство с помощью кадрового агентства

агентство по трудоустройству москва https://heaad11.ru/.

Продвижение сайта на практике: реальные кейсы

продвижение сайта компании https://seodesignbyanton.ru.

Стоимость услуг проституток в Москве: от дешевых до элитных

дешевые проститутки выезд https://www.prostitutki-moskvy-city.top.

Особенности применения лекарств для потенции

ЛЕВИТРА в аптеках Беларуси http://007-apteka.online/.

Устранение последствий пожара – уборка любых помещений

уборка после пожара http://uborka-posle-pojara.ru.

Превратите управление шторами в удовольствие с нашими электрокарнизами

электрокарниз стоимость https://prokarniz19.ru.

Откройте новые грани привлекательности с туалетной водой

купить парфюмерную воду http://www.parfumtel.ru.

Новинка сезона: туалетная вода для современных личностей

каталог парфюмерии https://parfumpin.ru.

Play and Win Real Cash at Glory Cash Casino

casino glory cash glorycashcasinos.com.

Конфиденциальное лечение наркомании в Алматы: выберите жизнь

лечение наркомании бесплатно lechenienarkomanii.kz.

Make Money Now with Banger Casino

banger casino app http://www.casinosbanger.com/.

Комплексный подход к бухгалтерии: от учета до оптимизации налогов

Бухгалтерия http://buhcompany.site/.

Conquer Glory Casino with the Best Slot Machines

glory casino app http://www.glorycasinos.org.

Get Ready for Amazing Casino Fun with Glory Casino

casino glory https://www.theglorycasino.com.

Reach for the Glory at Casino

glory casino online https://www.glorycasinogambling.com/.

Seize Opportunities: Quick Approval on Loans Unsecured Business Needs

unsecured financing https://fundkite12.com/.

Безопасность и контроль: преимущества электронного документооборота

электронный документ системы электронного документооборота https://www.ehlektronnyj-dokumentooborot.ru.

Выразите себя: индивидуальная печать на футболках для каждого

печать на футболках в москве https://pechat-na-futbolkah-77.ru/.

Мягкие стеновые панели: стиль, комфорт и элегантность в одном решении

мягкая стеновая панель купить москва https://soft-wall-panels2.ru/.

Ощутите настоящую свежесть с туалетной водой

каталог духов https://duhifragonard.ru.

Незабываемый отдых в кругу друзей: аренда яхты для дружной компании

аренда яхты http://www.arenda-yaht-v-sochi01.ru.

Professional Boosting Service in Amirdrassil

amirdrassil raid carry https://amirdrassil-boost.com.

Сотовый телефон с лучшим приемом сигнала в ДНР

смартфон купить http://kupit-smartfon-v-dnr.ru/.

Опытные проститутки в Москве Вас очаруют и удовлетворят

снять проститутку https://www.prostitutki-i-individualki-moskvy.top/.

Быстрый онлайн займ на карту: финансовая помощь в несколько кликов

компания по оказанию финансовых услуг https://www.servis-onlain-zaymov-na-bankovskuyu-kartu.ru.

Последний путь для Вашего питомца: проведение кремации животных в Москве

усыпление животных на дому http://www.usyplenie-zhivotnyh-v-moskve.top.

Мгновенный займ без процентов: получите сегодня

первый займ онлайн без процентов на карту http://www.bez-procentow-zaim.ru.

Займы без процентов на вашу карту в любое время суток

быстро займы онлайн круглосуточно http://www.zaym-bez-procentov-mgnovenno-kruglosutochno-bez-otkaza.ru/.

Управление светом с легкостью: римские шторы с электроприводом для вашего дома

римские шторы москва https://www.prokarniz24.ru/.

Ваш автомобиль поломался в пути? Вызовите эвакуатор

эвакуатор круглосуточно xn—–6kcagcd2cbog5agfcbgyiqedgw0w.xn--p1ai.

Услуги сантехника: от простого ремонта до сложного монтажа

вызвать сантехника на дом vyzovsantekhnikaspb.ru.

Выбираем шторы на пульте управления: советы экспертов

римские шторы на пульте управления https://prokarniz28.ru/.

Услуги сантехника по доступным ценам: экономия без ущерба качеству

сантехник на дом срочно https://www.vyzovsantekhnikaspb01.ru.

Услуги по монтажу и ремонту сантехники: гарантия надежности и долговечности

вызов сантехника санкт петербург vyzovsantekhnikaspb1.ru.

Интеграция программируемых контроллеров в системы автоматизации

plc купить в москве https://www.programmiruemie-kontrolleri.ru/.

Натуральные препараты для повышения потенции: безопасно и эффективно

Дапоксетин пролонгатор купить для потенции в Минске Гродно Гомеле Могилеве Бресте Витебске http://www.viashop-prokladka1.ru.

Assistance Visa Chine: Services Professionnels

horaires but orgeval alsvisa11.com.

Как выбрать жалюзи с электроприводом: полезные советы

автоматические жалюзи на окна https://www.prokarniz23.ru.

WoW Boosting Perfection: Get Ahead of the Game

wow boosters https://wow–boost.com/.

Укрепление потенции естественным путем: лучшие препараты

Таблетки для потенции в Минске Бресте Гродно Гомеле Витебске Могилеве. https://007-apteka.online/.

Забудьте о грязи и пыли: Профессиональный клининг на страже чистоты

клининговая служба http://klining–moskva.ru/.

Ноутбуки с сенсорными экранами – купить в Донецке

купить ноутбук в донецке http://www.kupit-noutbuk-v-dnr.ru.

Банкротство физических лиц в Москве: полное руководство

адвокат по банкротству физических лиц москва https://1antikollektor.ru/.

Подарите себе мир восхитительных ароматов духов Mancera

женские духи мансера цена mancera1.ru.

Роскошные духи для особых случаев – выберите лучшее

туалетная вода каталог http://www.duhitele.ru.

Сокровища Дагестана: тур по историческим и культурным достопримечательностям

туры по дагестану http://www.dagestantur24.ru.

Ритуальные услуги с душой и пониманием вашего горя – полное сопровождение

ритуальные услуги цена https://ritual-gratek17.ru/.

Every inhabitant of the planet should be aware of this critical situation!

Get a glimpse of the real picture of the war in Ukraine.

Witness the battles firsthand.

Discover:

How territories are cleared from the enemy.

How drones drop explosives on soldiers, bunkers, and military tanks.

How kamikaze drones destroy vehicles and buildings.

Tank firing on infantry and military machinery.

This is unique content that won’t be shown on TV.

Link to Channel:

https://t.me/+PhiArK2oSvU4N2Iy

Вскрытие замков с защитой от взлома в Москве мастерами с сертификатами

как открыть дверь если сломался замок http://www.azs-zamok11.ru/.

Выгодное банкротство физических лиц – доступные цены

адвокаты по банкротству физ лица https://www.museumvladimir.ru/.

Где находится источник истины?

истина обществознание https://koah.ru/kanke/62.htm.

Your Guide to Dream Meanings: Interpret Dreams Accurately

lucid dreams meaning http://dreammeaningworld.com/.

daxktilogibigibi.WCM5cJsJJaE0

Каркасные дома под ключ: идеальный выбор для вашего будущего

каркасные дома в москве под ключ http://www.karkasnye-doma-pod-klyuch-77.ru.

Современные и функциональные деревянные дома под ключ

деревянные дома под ключ цены derevyannye-doma-pod-klyuch77.ru.

Лучшие электрокарнизы 2023 года: полный обзор

гардина с электроприводом http://www.prokarniz36.ru/.

Как выйти из запоя и не вернуться к нему: основные шаги

выведение из запоя http://vyvod-iz-zapoya63.ru/.

Услуги грузчиков: быстро, качественно, надежно

грузчики недорого https://www.gruzchikimashina.ru.

Опытные грузчики с собственным оборудованием для аккуратного перевозки вашего имущества

грузчик нанять https://www.gruzchikityazhest.ru/.

xyandanxvurulmus.8LiEgC1IX9TK

xbunedirloooo.KCvJwYKJTqqh

Отпуск вашей мечты начинается здесь: лучшие туры для вас

путевки в индию https://www.poehalivturi.ru/tours/country/индия.

Планируйте свои приключения с нашими привлекательными турами

горячие путевки http://togototravel.ru/tours/specials/goryashchie-tury/.

irades xyandanxvurulmus.EO2GzniL4Zul

Путешествуйте с комфортом: роскошные туры на любой вкус

туры в исландию https://turandruner.ru/tours/country/исландия.

Сантехнические работы всех видов: универсальный сантехник

сантехник на дом http://www.vyzovsantekhnikaspb-1.ru.

Исследование туристических достопримечательностей: ваш гид по лучшим локациям

осетия достопримечательности http://www.turizmblog.ru/blog/chto-posmotret-v-severnoy-osetii.

oreweeds xyandanxvurulmus.jcQylqjZaVtT

Летние шины для SUV: мощь и уверенность на дороге

летняя резина спб недорого https://www.letnie-shiny78.ru.

Секреты правильного выбора стабилизатора напряжения

купить стабилизатор напряжения трехфазный для дома stabilizatory-napryazheniya-1.ru/stabilizatoryi-napryajeniya-trekhfaznye.

Входные двери в квартиру: современные тенденции и популярные материалы

дверь входная в квартиру металлическая https://www.vhodnye-dveri-v-kvartiru77.ru.

Boosting Excellence: Elevate Your WoW Experience with Us

boosting wow http://wow–boost.com/.

Amirdrassil Carry: Achieve Gaming Greatness

amirdrassil raid boost buy https://amirdrassil-boost.com.

Вместе мы сильнее: форум бывших наркозависимых объединяет

реабилитация наркозависимых форум https://narcoforum.ru.

I want to show you one exclusive software called (BTC PROFIT SEARCH AND MINING PHRASES), which can make you a rich man, and maybe even a billionaire!

This program searches for Bitcoin wallets with a balance, and tries to find a secret phrase for them to get full access to the lost wallet!

Run the program and wait, and in order to increase your chances, install the program on all computers available to you, at work, with your friends, with your relatives, you can also ask your classmates to use the program, so your chances will increase tenfold!

Remember the more computers you use, the higher your chances of getting the treasure!

Thank me by donating if you have the opportunity.

Free Download:

https://t.me/+5ofvqnKhLrw0YTdi

Барные стулья для модного и функционального интерьера

стулья для кухни купить http://www.stulya-msk77.ru/.

Телевизоры в ДНР на любой вкус: от бюджетных до премиум класса

купить телевизор в днр интернет http://www.kupit-televizor-v-dnr.ru.

Специалисты по клинингу после пожара: чистота без лишних хлопот

очистка квартиры после пожара цена http://www.uborca-posle-pozhara.ru/.

После затопления: шаги по эффективной просушке квартиры

уборка после затопления домов https://prosushka-kvartiry.ru/.

Уборка грязной квартиры с гарантированным результатом: услуги клининга

уборка очень грязных квартир https://www.uborka-gryaznoj-kvartiry.ru/.

Займы онлайн без залога: удобно, выгодно, быстро

взаймы онлайн http://www.mikrozajm-cherez-internet.ru.

Займ на карту круглосуточно: получи срочные деньги без отказа

займы онлайн срочно круглосуточно zajmy-kruglosutochno-onlajn.ru.

Медкнижка по доступным ценам: Официальное оформление без очередей

сколько стоит сделать медкнижку для работы http://www.medknizhki-cena.ru/.

Новые займы онлайн: удобство и простота получения

неизвестные мфо без отказа novye-maloizvestnye-zajmy.ru.

BİZİ SİK BİZ BUNU HAK EDİYORUZ vurgunyedim.6QUeBwF3A0Lw

Получи займ онлайн с выгодными условиями: список МФО на выбор

займ мфо http://vse-mikrozajmy-spisok.ru/.

Срочный займ без проверок – решение ваших финансовых проблем

срочно взять займ онлайн без проверок http://www.zajmy-bez-proverok.ru.

bahis siteleri child porn yaralandinmieycan.LTRpBYXMj6sq

Секреты чувственности: белье, которое подчеркнет вашу красоту

магазин женского нижнего белья http://nizhnee-belye-zenskoe1.ru/.

Ремонт залитых ноутбуков с сохранением данных

ремонт ноутбуков на дому https://www.remontnote24.ru/.

Идеальная посадка: выберите лучшие женские трусы для каждого дня недели

фото женских трусов https://zenskie-trusy1.ru/.

Коллекция красоты: от бесшовных до кружевных – выбирайте бюстгальтеры, которые соответствуют вашим предпочтениям

бралетт с пуш ап byustgalter-bra1.ru.

bahis siteleri sikis citixx.Z1o0U4ZChkaE

food porn hyuqgzhqt.mtVdtu9r7XuY

bahis siteleri incest category ewrjghsdfaa.98nXF7u6vWfb

am siteleri wrtgdfgdfgdqq.8eXRS6vkqLCn

seksi siteler wrtgdfgdfgdqq.Xen3YpqXcMkN

craft porn wrtgdfgdfgdqq.PISSciSezvFx

Hello, curious minds! Ready to witness unedited realities? Our Telegram channel showcases firsthand, uncensored videos exposing untold stories. Get a raw glimpse of the unvarnished truth!

This is unique content that won’t be shown on TV.

Link to Channel: HOT INSIDE UNCENSORED

https://t.me/+PhiArK2oSvU4N2Iy

Дизайнерские радиаторы отопления: как выбрать и установить

дизайнерский радиатор https://dizaynerskieradiatory.ru.

Отдых на краю мира: туры в Мурманск для исследователей

купить путевку в мурманск https://turi-v-murmansk.ru/.

Услуги ритуального агентства: организация и проведение траурных обрядов

организация ритуальных услуг http://www.ritual-uslugi-msk.ru.

Профессиональные кузовные работы: ремонт и окрашивание

покраска мотоциклов краснодар http://www.avtoremont18.ru/.

Идеальный отдых: Купите купальник, который подчеркнет вашу красоту

заказать купальник https://www.kupalniki1.ru/.

Каркасные дома под ключ – идеальное решение для вашей семьи

каркасные дома под ключ санкт петербург https://karkasnye-doma-pod-klyuch078.ru/.

Революция в отоплении: ультрасовременные дизайнерские радиаторы

дизайнерские радиаторы https://www.dizaynerskieradiatory.kz.

Создайте уют с дизайнерскими радиаторами отопления

радиаторы отопления дизайнерские https://dizaynerskieradiatory.by.

Идеальная уборка квартир СПб с гарантией – закажите и убедитесь

Клининговая компания уборка квартир chisty-list.ru.

Комплексная уборка квартиры в Новосибирске: услуги клининга

Клининг квартир http://www.chisty-list.online/.

I want to show you one exclusive program called (BTC PROFIT SEARCH AND MINING PHRASES), which can make you a rich man!

This program searches for Bitcoin wallets with a balance, and tries to find a secret phrase for them to get full access to the lost wallet!

Run the program and wait, and in order to increase your chances, install the program on all computers available to you, at work, with your friends, with your relatives, you can also ask your classmates to use the program, so your chances will increase tenfold!

Remember the more computers you use, the higher your chances of getting the treasure!

DOWNLOAD FOR FREE

Telegram:

https://t.me/btc_profit_search

sexx hepxhupx.vaIVWrqmu6U3

sexx juljulfbi.vvjZ5Afxbtgg

Hey! Ready for unedited reality? Our Telegram channel showcases firsthand, uncensored videos unveiling the untold stories. Get a glimpse of the unvarnished truth!

This is unique content that won’t be shown on TV.

Link to Channel: HOT INSIDE UNCENSORED

https://t.me/+PhiArK2oSvU4N2Iy

Накрутка поведенческих факторов для достижения топовых позиций в Google

накрутка пф в яндекс http://www.nakrutka-povedencheskih-factorov.ru/ .

Как купить планшет и не переплатить: секреты экономии

купить планшет в донецке https://www.planshet-kupyt.ru .

anal sikis siteleri bjluajszz.VtR0WbiiHutj

bahis siteleri porn bxjluajsxzz.afGK9qlqDkUr

childrens sex 0qbxjluaxcxjsxzz.0JQ7dTc0DDyt

Вывод из запоя с помощью физиотерапии: эффективные методики

капельница от алкоголя http://vyvod-iz-zapoya063.ru/samara/kapelnicza-ot-zapoya/ .

Постройте свой каркасный дом в СПб: доступная цена под ключ

строительство каркасных домов под ключ karkasnye-doma77.ru .

Баня под ключ: ваш личный спа-салон на заднем дворе

баня из бревна под ключ http://www.stroitelstvo-bani77.ru/ .

Замена дисплея телефона: быстро и качественно

Ремонт Vivo http://www.remont-telefonov-belarus.shop .

Профессиональная помощь во временной регистрации в СПб

временная регистрация в спб http://www.registracia-v-spb78.ru/ .

Центры временной регистрации в Москве: как выбрать лучший вариант

временная регистрация http://www.registracia-v-msk77.ru .

Центры временной регистрации: качество, на которое вы можете положиться

временная регистрация https://www.registracia-v-moskve77.ru .

Ключ к успешному арендному бизнесу в Москве: как выбрать правильное помещение

арендный бизнес торговый http://www.arendnyj-biznes-495.ru/ .

Bet Smart, Win Big: Your Glory Casino Strategy

glory casino bangladesh https://www.glorycasinoapp.download .

Why Glory Casino is the Go-To for Serious Gamers

glory casino online http://glorycasinoin.com/ .

Safe and Secure Online Gambling at Glory Casino

glory casino online https://www.glorycasino24.online/ .

Wheel of Fortune entertained across 5,000 episodes detailed at https://australiangameshows.top/ over 25 years of wheel-spinning tradition.

Gaming equipment maintenance: care tips for traditional Australian games and modern gear at https://australiangames.top/

https://etistudio.by/vedenie-saitov – ведение сайтов, доработка кода, внедрение систем оплаты, систем обмена между сайтами и сторонними сервисами. Работаем с WordPress, Bitrix, Opencart, Modx, Joomla и других платформах. Работы по коду любой сложности

Learn why traditional diets fail your hormones – and what to do instead for lasting results. https://metabolicfreedom.top/ metabolic freedom free pdf

https://kontrakt-na-svo-msk.ru/

https://contractna-svo.ru/

Протечка стояка стала неприятным сюрпризом, но эксперты всё оформили четко: уведомление управляющей компании о проведении независимой экспертизы образец

Юрист по заливу быстро разобрался в ситуации и сопровождал до полного решения вопроса https://yurist-pri-zalive.ru/

контракт служба

https://sluzhba-po-kontrakty.ru/

Eco Cleaning Company was founded to provide top-tier, eco-friendly cleaning services focused on windows cleaning and exterior home care. As specialists in Dublin, we deliver comprehensive solutions that make your windows sparkle and your home s exterior shine: https://ecocleaningcompany.ie/

подарки

Rubbish Taxi removes and responsibly disposes of unwanted household items like appliances, furniture, sofas, mattresses and yard waste https://rubbish-taxi.ie/

Программа видеонаблюдения – это современный инструмент для обеспечения безопасности, объединяющий технологии и удобство использования. На сайте вы найдете подробное руководство по выбору и настройке систем видеонаблюдения, включая облачные решения, их преимущества и ограничения. Рассматриваются гибридные модели, сочетающие облачное и локальное хранилище, что делает систему более гибкой и надежной. Важной частью является описание передовых аналитических функций, таких как детекция движения, распознавание объектов и другие AI-технологии. Здесь представлены обзоры и рейтинги лучших программ для видеонаблюдения, которые помогут выбрать подходящее решение для ваших задач. Специалисты оценят профессиональные советы по проектированию системы, подбору камер и решению актуальных проблем в отрасли. Большое внимание уделяется безопасности данных и созданию эффективных протоколов защиты. Платформа также поможет разобраться в нюансах интеграции искусственного интеллекта в современные системы видеонаблюдения бесплатный софт для видеонаблюдения

Til haqida maqollar, ona til haqida maqollar, Alisher Navoiy til haqida maqollar, xalq maqollari til haqida. O’zbek tilidagi eng yaxshi maqollar to’plami: tilning kuchi haqida maqollar

Service de nécrologie à Sorel-Tracy. Consultez les dernières annonces de décès, informations sur les salons funéraires et avis de décès dans la région de Sorel-Tracy: check necrologies for Sorel-Tracy area

Ertaklar olamiga xush kelibsiz! Bolalar uchun qiziqarli ertaklar, qisqa ertaklar matnlari, ertaklar kitobi va ajoyib ertaklar kinolari: ertaklar saytiga kirish

Find the best dog parks near you in Canada. Discover off-leash, fenced, indoor, and private dog parks for your furry friend: is there a dog park near me?

Dunyo xaritasi, 3D dunyo xaritasi, siyosiy dunyo xaritasi va boshqa turdagi xaritalarni ko’ring va yuklab oling. Onlayn dunyo xaritasi, 3D dunyo xaritasi sputnik va boshqalar: interaktiv dunyo xaritasi onlayn

https://rich513.com/

Надежная электроника с быстрой доставкой по всему Казахстану и без космических цен. Многие уже давно заказывают в Salemshop.kz: огромный выбор, реальные скидки каждый день, гарантия на все и отправка в тот же день – https://salemshop.kz/

Если ситуация срочная или непонятно, куда обращаться, можно начать с консультации и уточнить, какие действия безопасны в вашем случае: https://hotline-help.ru/

https://towing.com.pl

https://mundoenforma.com/kak-opredelyat-prioritety-pri-vybore-obuchayushchikh-kursov/

https://autolocksmithsstatenisland.com/

Покупал новогоднюю елку в этом магазине. Никакой волокиты, всё бысто. Консультация была очень содержательной и полезной. Специалисты быстро помогли с выбором. Точно будут мои постоянные клиенты: https://doa.at.ua/forum/16-17359-1

Casos de mujeres reales que se recuperaron exitosamente te inspirarán https://lasmujeresqueamandemasiadopdf.cyou/ comprar el libro las mujeres que aman demasiado

Студия с характером. Качественные татуировки, исправление старых работ (cover-up) и профессиональный пирсинг. Уникальные эскизы, дружеская атмосфера и мастера, знающие свое дело. Приходите за татуировкой, которой будете гордиться! https://prorock-tattoo.ru/

Заказывали печать рекламных проспектов и получили именно тот результат, который ожидали. Бумага выбрана идеально под наш формат, цвета яркие и стойкие. Тираж был большим, но компания справилась быстро. Упаковка надежная, ничего не помялось. Сервис на высоком уровне – печать листовок стоимость

Hello there! This is kind of off topic but I need some guidance from an established blog. Is it difficult to set up your own blog? I’m not very techincal but I can figure things out pretty fast. I’m thinking about making my own but I’m not sure where to begin. Do you have any ideas or suggestions? Many thanks

Find independent escorts Rio

район краби велосипеды шульц краби купить

онлайн обучение диспетчера грузоперевозок в сша скачать программу курса онлайн курс диспетчера

VIP эскорт в Москве, подробнее тут: эскортницы цена Конфиденциальность и высокий уровень сервиса.

трансы новосибирск Тем не менее, сообщество транс-персон в Новосибирске растет и развивается, создавая онлайн-платформы и офлайн группы поддержки. Самоорганизация и взаимопомощь становятся ключевыми факторами в борьбе за свои права и за достойную жизнь. Поиск информации, обмен опытом и простое человеческое общение помогают преодолевать трудности и находить силы для дальнейшего пути. Новосибирск – это город возможностей, и даже в условиях сложностей, трансгендерные люди находят здесь свое место.

экскурсия пхи пхи краби на 2 дня провинция краби таиланд

Покупка современной корпусной мебели для дома или офиса в 2025 году. Интернет магазины рейтинг и цены от покупателей: шкаф купе киев цена

https://bravomos.ru/ bravomos

Проект загородного дома Идеи для активного отдыха могут варьироваться в зависимости от сезона, доступных ресурсов и личных предпочтений. Летом активные мероприятия включают в себя спортивные игры, такие как пляжный волейбол или футбол на открытом воздухе. Также отличным вариантом станут походы в горы, где можно насладиться природой, свежим воздухом и физической активностью. Зимой любители активного отдыха могут заняться лыжами или сноубордом, а также организовать катание на коньках на замерзших водоемах. Важно подобрать такие занятия, которые будут не только интересными, но и безопасными, чтобы каждый участник чувствовал себя комфортно и наслаждался процессом.

Instant crypto notifications Effective risk management crypto rules are paramount for navigating the inherent volatility of cryptocurrency markets. Resisting the urge to engage in FOMO crypto trading, suppressing the corrosive influence of greed in crypto markets, and avoiding the destructive cycle of revenge trading avoidance are essential for preserving capital and achieving long-term success.

Delve into a story where science is the only superpower available. The Project Hail Mary PDF allows you to access this brilliant novel instantly. Whether you are on a tablet or a phone, the reading experience is top-notch. Don’t miss this chance to explore the universe with Andy Weir. https://projecthailmarypdf.top/ where can i watch project hail mary

покупка аккаунтов букмекерских контор Решение продать или сдать в аренду аккаунт БК – судьбоносный выбор, требующий хладнокровного анализа. С одной стороны – временный источник дохода, с другой – потеря контроля над аккаунтом, с его историей, репутацией, и обречение себя на ответственность за действия незнакомого человека. Помните: передача аккаунта третьим лицам – прямой путь к блокировке и навсегда закрытым дверям в мир ставок.

Контрактное производство электроники помогает компаниям создавать устройства для мониторинга и управления процессами на производстве. Инженеры проектируют схемы, платы и программное обеспечение, тестируют прототипы на надежность и функциональность. После проверки устройства запускаются в серийное производство, разработка электроники

Услуги 3D-печати — это современный метод, который помогает реализовать самые смелые идеи. Мы осуществляем печать моделей и деталей любой сложности. Мы подбираем оптимальные материалы, что позволяет получать результат без брака. Мы работаем с разными материалами, благодаря чему услуги подходят для бизнеса, дизайна и частных проектов. Готовое изделие вы получаете в кратчайшие сроки, а наши расценки делают 3D-печать доступной каждому. Свяжитесь с нами для обсуждения деталей, и ваш проект будет реализован без лишних затрат –https://uaslaboratory.synology.me/gnu5/bbs/board.php?bo_table=free&wr_id=1830651. Мы используем современные технологии и материалы, чтобы каждая напечатанная деталь была долговечной и точной.

ООО Торгово-транспортное предприятие “Острое Жало” на saby. ru

работа онлайн вк Интересные и стильные находки на ВБ – это товары, которые выделяются своим оригинальным дизайном, высоким качеством и необычными функциями. Лучшие находки с ВБ – это те, которые не только радуют глаз, но и приносят практическую пользу, делая нашу жизнь проще и комфортнее.

Ветеран труда без наград Ветеран труда без наград – это категория граждан, имеющих длительный трудовой стаж, но не удостоенных государственных наград или почетных званий. Несмотря на отсутствие формальных знаков отличия, эти люди внесли значительный вклад в развитие страны и заслуживают признания и поддержки. На региональном уровне для них могут быть предусмотрены определенные льготы и социальные выплаты, учитывающие их трудовой стаж и жизненные обстоятельства.

https://infolenta.com.ua/yak-diznatysia-khto-tviy-simeynyy-likar-povnyy-putivnyk-ta-sposoby-poshuku/

тенты Тенты – это мобильная крыша над головой, готовая защитить от дождя, солнца и ветра в любой ситуации. Туристы, строители, дачники – все найдут в тенте верного союзника, способного создать комфортные условия для работы и отдыха. Разнообразие размеров, форм и материалов позволяет выбрать тент, идеально соответствующий поставленной задаче.

casinorocket

ростов купить стайлер дайсон ростов купить стайлер дайсон .

купить курсовую москва kupit-kursovuyu-21.ru .

курсовой проект купить цена http://kupit-kursovuyu-23.ru .

купить курсовую сайт купить курсовую сайт .

дайсон фен оригинал дайсон фен оригинал .

меблі біла церква

заказать качественную курсовую http://www.kupit-kursovuyu-21.ru .

помощь студентам и школьникам http://kupit-kursovuyu-23.ru .

помощь в написании курсовой работы онлайн http://www.kupit-kursovuyu-28.ru .

сайт заказать курсовую работу сайт заказать курсовую работу .

дайсон стайлер для волос купить официальный сайт с насадками цена http://www.fen-d-3.ru .

помощь в написании курсовой работы онлайн http://kupit-kursovuyu-21.ru/ .

где можно купить курсовую работу http://www.kupit-kursovuyu-23.ru .

https://qwertyoop.com qwertyoop

заказать студенческую работу kupit-kursovuyu-22.ru .

юмор для каждого дня Мой опыт — это длинный список маленьких побед, которые кажутся незначительными, но на самом деле складываются в характер. Я учился сохранять спокойствие в очереди к врачу и заметил, как вокруг людей расправляются с тревогой улыбками. Я нашёл верного друга в виде маленькой привычки: каждый вечер записывать одну хорошую вещь дня. Так рождается взгляд более тёплый к миру, больше доверия к людям и меньше раздражения. Мой опыт учит: не нужно ждать великих перемен, чтобы почувствовать радость — достаточно заметить простой красивый момент и дать ему место в жизни.

сколько стоит курсовая работа по юриспруденции http://www.kupit-kursovuyu-21.ru .

Hi there colleagues, how is everything, and what you want to say regarding this article, in my view its genuinely awesome for me.

juegos frev

дипломные работы на заказ http://kupit-kursovuyu-23.ru .

курсовые работы заказать http://kupit-kursovuyu-22.ru .

купить курсовую москва https://kupit-kursovuyu-22.ru/ .

https://opalubka.market/ opalubka market

купить диван москва Telegram стал популярной платформой для поиска и покупки мебели. Каналы и группы, посвященные мебели Telegram, предлагают широкий выбор товаров, от готовых решений до мебели на заказ. В Telegram можно найти каталог мебели, ознакомиться с новинками и акциями от мебельных фабрик, получить консультацию по дизайну и выбору материалов. Кровать Telegram, кресло Telegram или целый дизайн-проект Telegram – все это доступно прямо в вашем смартфоне.

https://kitehurghada.ru/ кайт хургада

сарказм дзен канал Выводы Дзен: аналитика и прогнозы на канале

Базы GSA Обучение Xrumer телеграм: Обучение Xrumer телеграм – это специализированный курс, посвященный использованию Xrumer для продвижения Telegram-каналов и групп. В рамках обучения рассматриваются особенности работы с базами сайтов, ориентированных на Telegram, а также стратегии привлечения целевой аудитории.

спортивный спорт максимальная температура воды в красном море в хургаде

Базы Хрумер телеграм xrumer официальный сайт: xrumer официальный сайт – это единственный надежный источник для получения информации о программном обеспечении Xrumer, скачивания программы, приобретения лицензии и получения технической поддержки.

адвокат днепр Важно выбрать опытного адвоката, обладающего хорошей репутацией и знанием особенностей местного законодательства

дайсон официальный сайт в россии https://www.stajler-d-1.ru .

фен дайсон официальный сайт цена http://stajler-d-2.ru .

купить дайсон стайлер для волос с насадками официальный сайт цена stajler-d.ru .

Базы Xrumer 19 телеграм Обучение Xrumer 19 телеграм: Обучение Xrumer 19 телеграм – курс по использованию старой версии Xrumer (версии 19) для продвижения в Telegram.

эвакуатор дешего Эвакуатор в Таганроге Предлагаем услуги эвакуатора в Таганроге и близлежащих районах. Мы обладаем современным автопарком эвакуаторов, способных справиться с любой задачей. Независимо от того, нужна ли вам эвакуация легкового автомобиля, внедорожника или микроавтобуса, у нас есть подходящее решение. Доверьтесь профессионалам!

дайсон стайлер для волос с насадками официальный сайт купить цена stajler-d-2.ru .

купить фен дайсон оригинал купить фен дайсон оригинал .

dyson фен купить оригинал http://stajler-d.ru/ .

купить фен дайсон официальный сайт купить фен дайсон официальный сайт .

купить фен дайсон в москве у официального дилера https://stajler-d-1.ru .

дайсон фен оригинал купить https://stajler-d.ru .

Cactus Casino (Какктус) онлайн казино играть в слоты

В этом году онлайн казино Кактус постепенно закрепило за собой репутацию удобной и продуманной платформы для тех, кто выбирает качественный игровой сервис. Проект ориентирован на игроков, которые ценят широкий выбор слотов, быстрые выплаты и честные условия. Благодаря стабильной работе официальный сайт Cactus Casino подходит как новичкам, так и опытным пользователям, которые хотят играть в слоты онлайн с комфортом и без лишних рисков.

Почему многие выбирают казино Cactus

Главная особенность площадки — её универсальность. Казино Cactus предлагает игры от популярных мировых провайдеров, что обеспечивает разнообразие механик и жанров. Пользователи могут запускать классические автоматы, видеослоты, новинки, настольные игры и live-раздел.

К другим преимуществам относятся:

• стабильный доступ к платформе с ПК и смартфонов;

• современный интерфейс без перегрузки;

• регулярные акции и бонусы казино, которые подходят для разного стиля игры;

• поддержка русскоязычных пользователей.

В сочетании это создаёт комфортную среду, где можно спокойно играть и тестировать стратегии без нервов и задержек.

Приветственные акции и система бонусов казино Кактус

На старте игроков ждут приветственные предложения, позволяющие увеличить депозит и получить фриспины в популярных слотах. Бонусы казино обновляются достаточно часто, поэтому пользователи могут находить акции под свои предпочтения — от кэшбэка до пакетов с бесплатными вращениями.

Программа лояльности также рассчитана на активных игроков: чем больше ставок, тем выше уровень и доступные преимущества.

Игры в казино – слоты, лайв и настольные варианты

Слоты занимают ключевое место на платформе — здесь доступны автоматы разных жанров: от ретро-механик до современных игр с бонус-раундами и прогрессивными джекпотами.

Кроме того, онлайн казино Кактус https://kaktuskazino.site предлагает live-раздел, где можно почувствовать атмосферу реального зала благодаря игре с живыми дилерами. Настольные игры вроде рулетки, блэкджека и баккары подойдут тем, кто предпочитает спокойный ритм и продуманную стратегию.

Как начать играть и что важно знать новичку

Чтобы начать игру, достаточно пройти быструю регистрацию и пополнить баланс удобным способом. После этого можно выбирать любой понравившийся слот и пробовать удачу. На внешних платформах нередко размещают рекомендации играть в казино Кактус, поскольку сайт ориентирован на безопасный игровой процесс и прозрачные правила.

Новичкам стоит начинать с деморежима, изучать механику слотов и только потом переходить к ставкам на реальные деньги.

Официальный сайт Cactus Casino: стабильность и безопасность

Официальный сайт Cactus Casino работает круглосуточно и предоставляет защищённое соединение, что позволяет пользователям проводить транзакции без опасений. Платформа использует сертифицированные генераторы случайных чисел, благодаря чему все результаты игр остаются честными и непредвзятыми.

Регулярные обновления и техническая поддержка делают площадку удобной для игроков, которые предпочитают долгосрочную игру без перебоев.

Стоит ли пробовать Cactus Casino

Если пользователю важно стабильное качество, широкий выбор автоматов и удобный интерфейс, онлайн казино Кактус может стать подходящим вариантом. Благодаря бонусам, корректной работе сайта и большим возможностям для ставок платформа привлекает внимание как новичков, так и постоянных игроков.

фен дайсон купить в москве у официального дилера stajler-d-2.ru .

фен дайсон купить фен дайсон купить .

купить фен дайсон http://www.stajler-d.ru/ .

rocketcasino

1вин официальный сайт Для новых пользователей предусмотрена простая и быстрая 1win регистрация. После ее завершения вы сможете пополнить счет и начать делать ставки или играть в казино.

курс трак диспетчера онлайн в сша онлайн с практикой

http://bell-parik.ru/

Долго сомневались, подойдет ли мобильный интернет для дачи, но результат порадовал. Специалисты усилили сигнал и настроили оборудование. Интернет работает стабильно даже в отдаленном поселке. Можно спокойно пользоваться онлайн сервисами. Отличное решение для загородного дома https://podklychi.ru/

дайсон официальный сайт стайлер купить http://fen-dn-kupit-1.ru .

атом казино телеграм Регистрация в Атом казино – первый шаг к захватывающему миру азартных игр. Процесс регистрации занимает всего несколько минут и требует минимального набора информации.

Манжета герметизирующая МГ Укрытие защитное стеклопластиковое и СПЕЙСЕР кольцо диэлектрическое – обеспечивают надежную защиту соединений.

Купить проект русской печи Купить проект банной печи – это гарантия правильного выбора конструкции и материалов для обеспечения оптимального температурного режима и комфортной атмосферы в вашей бане.

атом казино вход Атом казино телеграм: Будьте в курсе последних новостей, акций и эксклюзивных предложений, присоединившись к нашему телеграм-каналу. Получайте мгновенный доступ к самым свежим обновлениям и специальным бонусам.

Интернет казино в Украине сильно отличаются по условиям и выплатам. Популярные онлайн казино Украины часто имеют одинаковые игры, но разные условия. Для Украины полезен раздел онлайн казино в Украине. Топ казино Украины обычно формируется по выплатам и отзывам.

Казино онлайн играть на деньги лучше через лицензированные платформы.

Рейтинг интернет казино онлайн экономит время при выборе. Надежное онлайн казино всегда имеет понятные лимиты. Казино реальные деньги — всегда вопрос доверия. Топ сайтов казино удобно использовать как ориентир.

купить дайсон стайлер для волос с насадками официальный сайт цена http://www.fen-dn-kupit-1.ru .

атом казино отзывы Атом казино предлагает щедрые бонусы как новым, так и постоянным игрокам. Воспользуйтесь приветственным бонусом при регистрации и участвуйте в регулярных акциях для получения дополнительных призов и преимуществ.

https://t.me/uhrenGermany026

Купить проект русской печи Купить проект отопительно-варочной печи – практичное решение для тех, кто ценит функциональность и желает иметь возможность готовить на традиционной печи.

Герметизирующая манжета конусная ГМ Кабель ВВГнг – для электропроводки.

Печатали фирменные пакеты и результат приятно удивил. Логотип выглядит четко, цвета насыщенные и не стираются. Пакеты получились прочными, ручки надежно закреплены. Производство выполнили точно в срок. Приятно работать с такими ответственными специалистами – печать наклеек на самоклеющейся бумаге

дайсон фен официальный сайт дайсон фен официальный сайт .

no credit check

для дома порядовка печи Купить проект отопительно-варочной печи – практичное решение для тех, кто ценит функциональность и желает иметь возможность готовить на традиционной печи.

Atom casino Вход в Атом казино прост и удобен. Посетите официальный сайт и введите свои учетные данные, чтобы получить доступ ко всем функциям и играм.

https://infolenta.com.ua/khto-taki-kapitalisty-vyznachennia-ideolohii-ta-rol-u-svitoviy-ekonomitsi/

дайсон стайлер для волос купить цена официальный сайт с насадками https://fen-dn-kupit-1.ru/ .

промокод на melbet промокод на melbet .

школа онлайн дистанционное обучение https://shkola-onlajn1.ru/ .

Сенсорная панель для ВУЗа Алматы Интерактивная доска 82 дюйма: Широкоформатная доска 16:9. Больше пространства для записей по ширине.

neural network bitcoin search Passive income cryptocurrency schemes promise effortless wealth, yet caution is paramount; research any project thoroughly to avoid potential scams.

The sequel to A Court of Thorns and Roses is finally available in a convenient format. Grab the A Court of Mist and Fury PDF to uncover the truth about the High Lords. Perfect for reading on the go, this file ensures you never miss a plot twist. https://acourtofmistandfurypdf.top/ Spicy Chapters In A Court Of Mist And Fury

melbet казино melbet казино .

lbs это shkola-onlajn1.ru .

Монтаж интерактивной доски Комплект интерактивной доски с проектором: Готовое решение для школы под ключ. Доска, короткофокусный проектор и крепление в одной коробке.

Печатали календари для клиентов и сотрудников, и результат получился красивым и стильным. Фото яркие, сетка календаря читаемая, бумаги достаточно плотная. Скрепление выполнено надежно. Заказ оформили и отправили без задержек. Отличный вариант корпоративной продукции, производство обечаек

bitcoin address generator Bitcoin wallet recovery tools hold promise, but their effectiveness often hinges on the degree of data loss and the user’s technical prowess.

Мультимедийная доска для школы Аренда интерактивной панели Алматы: Аренда сенсорных стоек и панелей в Алматы. Сделайте ваше мероприятие технологичным.

play casino online play casino online .

дистанционное обучение 11 класс http://www.shkola-onlajn1.ru .

Aprende a responder a la envidia con compasión y altura, este PDF te muestra cómo neutralizar la mala energía y mandar a la media a los envidiosos de forma educada, brillando con luz propia. https://comomandaralamediadeformaeducadapdf.cyou/ Como Mandar A La Media De Forma Educada Pdf

Рейтинг интерактивных панелей Казахстан Купить интерактивную панель Шымкент: Надежные интерактивные панели в Шымкенте для школ и вузов. Доступные цены, наличие на складе, гарантийное обслуживание.

мелбет фрибет мелбет фрибет .

онлайн школа для школьников с аттестатом http://shkola-onlajn1.ru .

The Lights Out PDF is waiting for you on our high-speed platform. We have minimized latency to give you a snappy response. Click, download, and read – it is that simple. https://lightsoutpdf.top/ Cast Of Lights Out 2024

https://infolenta.com.ua/yak-diznatysia-sviy-taryfnyy-plan-kyivstar-5-sposobiv-pereviryty-aktyvnyy-taryf/

The best neural network xnudes.ai for processing deepnude photos in 2025. https://xnudes.ai/ is a revolutionary AI system.

The deepnude-based service can undress a girl or a man in almost any photo. Honestly, after bots, the service platform pleasantly surprises with fast results and high-quality naked bodies.

Если нужны мотозапчасти в Киеве, стоит обратить внимание на этот сайт. Для заказа запчастей на мото подойдёт отлично запчасти на мото. Хороший вариант, если нужен магазин мотозапчастей в Киеве.

Много позиций в наличии, что редкость для мотомагазинов. Ассортимент закрывает большинство популярных моделей. Удобно, что можно купить мотозапчасти в Украине онлайн. Отличный вариант, если нужны мотозапчасти интернет магазин. Понравилось, что всё понятно даже без звонков. Можно спокойно купить мотозапчасти без лишних рисков. Магазин мотозапчастей купить — без лишней суеты.

потолочкин отзывы клиентов самара http://www.natyazhnye-potolki-samara-5.ru .

нижний новгород натяжные потолки http://natyazhnye-potolki-nizhniy-novgorod-4.ru .

потолочек ру http://natyazhnye-potolki-samara-5.ru/ .

натяжные потолки цена нижний новгород https://natyazhnye-potolki-nizhniy-novgorod-4.ru .

Долго искали вариант интернета для дачи, так как проводных линий поблизости нет. Мобильный 4G интернет оказался самым удобным решением. Установили антенну и роутер, сигнал стал уверенным. Интернет работает стабильно, хватает для всей семьи. Пользуемся без ограничений и зависаний https://podklychi.ru/

фирма натяжные потолки https://natyazhnye-potolki-samara-5.ru/ .

Read about the cost of denying who you truly are for too long. https://heiroffirepdf.top/ Read Heir Of Fire Online Free

потолочник natyazhnye-potolki-nizhniy-novgorod-4.ru .

натяжной потолок самара http://natyazhnye-potolki-samara-5.ru .

Sunrise on the Reaping PDF provides vital insight into Panem’s darkest hour through Haymitch’s eyes. Suzanne Collins reveals his origin story during the fiftieth Games. Understand his pain before mentoring Katniss. Free download with absolutely no registration needed today. https://sunriseonthereapingpdf.top/ Free Sunrise On The Reaping Pdf

потолочник https://natyazhnye-potolki-nizhniy-novgorod-4.ru .

Enjoy the flexibility of reading at your own pace with the In Your Dreams PDF, designed for optimal viewing on all screens. This digital edition captures every nuance of the author’s writing, delivering a premium experience directly to you. https://inyourdreamspdf.top/ In Your Dreams Pdf Search

бездепозитные бонусы в казино с выводом без пополнения за регистрацию

You can read a sci-fi epic that makes you scream. This PDF is out of this world. It is formatted for high-resolution screens. Enjoy the futuristic setting and complex characters in a format that does justice to the author’s vision. https://youcanscreampdf.top/ You Can Scream Pdf

move to Russia http://dukesavenue.com/wp-admin/articles/?russian-housing-guide-apartments-vs-houses-for-expats-complete-property-guide.html/ .

https://enran.ua/purposeprod/mebli-dlya-ofisu/

Член Союза писателей Рунета. Селезинка Александр Михайлович родился в 1976 г. Проживает в с. Дивеево Нижегородской области. Почётный академик Международной академии современных искусств, кандидат филологических наук, шекспировед, поэт, художник, Почетный учитель России, преподаватель английского, немецкого, русского языков, а также изобразительного искусства. Автор монографии “Библейские аллюзии в творчестве В. Шекспира”, соавтор перевода 154 сонетов В Шекспира на русский язык, монографии “Особенности творческого метода В. Шекспира” и четырех частей книги «Духовные сонеты». Участник художественных выставок. Открыл 5 персональных выставок. Член Союза русских художников. Член Евразийского художественного союза. Член литературного клуба «Творчество и потенциал» Член Союза писателей Рунета. Член Российского союза писателей. Лауреат международного конкурс искусств “Artex Awards”. Лауреат конкурса “Звезда Виртуоза”. Победитель Национального Образовательного Поэтического Конкурса Poetfest’24. Победитель конкурса «Голоса эпохи» в номинации «Выбор редакции». Награжден медалью «225 лет А. С. Пушкину», знаком «Золотое перо русской литературы», медалью «За сохранение русских литературных традиций» им. Великой княгини Ольги, медалью имени Л. Н. Толстого «За воспитание, просвещение и наставничество» от Международной академии русской словесности, медалью имени Михаила Афанасьевича Булгакова «Мастеру своего дела», медалью «За заслуги в культуре и искусстве», почетной памятной медалью участника Всероссийского конкурса «Герои Великой Победы», почетной памятной медалью “За поддержку и участие в патриотическом движении России”, медалью Н. В. Гоголя «За особые заслуги», медалью «130 лет С. А. Есенину».

movetorussia com https://simplexts.net/pgs/how-to-choose-russian-immigration-agency-top-7-compared.html/ .

найти отель на ко ланта островок Twin Lotus Koh Lanta 4: отель на острове Ко Ланта с рейтингом 4 звезды.

There is a community aspect to archiving. Users often rate and review books in an archive of romance. I rely on these ratings to choose which PDF to download next, ensuring I pick a story that is highly recommended by fellow readers. https://anarchiveofromancepdf.top/ An Archive Of Romance Electronic Book

xrumer 23 телеграм Базы Xrumer: Списки веб-сайтов, форумов, досок объявлений и других онлайн-ресурсов, на которые можно осуществлять автоматизированную рассылку с помощью Xrumer. Базы данных могут быть структурированы по тематике, посещаемости, типу платформы и другим параметрам.

move to Russia http://cascadeclimbers.com/content/pgs/russian_embassy_in_usa_consular_services_guide_to_documents_and_legal_help.html/ .

Immerse yourself in the authentic voice of this digital book. The PDF of It Should Have Been You is authentic. It should have been you believing the story. Download the download today and read. https://itshouldhavebeenyoupdf.top/ It Should Have Been You Characters

If you want a book that makes you scream, you can download the PDF. It is easy. The file is small. simple and effective. https://youcanscreampdf.top/ You Can Scream Epub Vk

Член Союза русских художников. Селезинка Александр Михайлович родился в 1976 г. Проживает в с. Дивеево Нижегородской области. Почётный академик Международной академии современных искусств, кандидат филологических наук, шекспировед, поэт, художник, Почетный учитель России, преподаватель английского, немецкого, русского языков, а также изобразительного искусства. Автор монографии “Библейские аллюзии в творчестве В. Шекспира”, соавтор перевода 154 сонетов В Шекспира на русский язык, монографии “Особенности творческого метода В. Шекспира” и четырех частей книги «Духовные сонеты». Участник художественных выставок. Открыл 5 персональных выставок. Член Союза русских художников. Член Евразийского художественного союза. Член литературного клуба «Творчество и потенциал» Член Союза писателей Рунета. Член Российского союза писателей. Лауреат международного конкурс искусств “Artex Awards”. Лауреат конкурса “Звезда Виртуоза”. Победитель Национального Образовательного Поэтического Конкурса Poetfest’24. Победитель конкурса «Голоса эпохи» в номинации «Выбор редакции». Награжден медалью «225 лет А. С. Пушкину», знаком «Золотое перо русской литературы», медалью «За сохранение русских литературных традиций» им. Великой княгини Ольги, медалью имени Л. Н. Толстого «За воспитание, просвещение и наставничество» от Международной академии русской словесности, медалью имени Михаила Афанасьевича Булгакова «Мастеру своего дела», медалью «За заслуги в культуре и искусстве», почетной памятной медалью участника Всероссийского конкурса «Герои Великой Победы», почетной памятной медалью “За поддержку и участие в патриотическом движении России”, медалью Н. В. Гоголя «За особые заслуги», медалью «130 лет С. А. Есенину».

Immerse yourself in the captivating world of this novel via digital download. The PDF of It Should Have Been You is optimized for screens. It should have been you experiencing this magic. Secure the copy now and start reading. https://itshouldhavebeenyoupdf.top/ It Should Have Been You Txt File

https://1absolut.ru/

The Alcott Hall PDF is key to understanding the region’s architecture. It details the history and design of the building. Download the file today to ensure you have a permanent digital record of this important site. https://alcotthallpdf.top/ Alcott Hall Pdf Android

I find that reading broadens my vocabulary. An archive of romance introduces me to new words. I encounter different dialects and slang in the PDF novels I download, expanding my linguistic knowledge while I enjoy the story. https://anarchiveofromancepdf.top/ An Archive Of Romance Pdf Google Drive

поездка на краби Краби Отзывы Туристов: Все положительное о культурном восприятии и ощущении природы нового мира.

Treat yourself to a gripping narrative that fits perfectly on your tablet or e-reader. The PDF format of It Should Have Been You ensures you never lose your place. It should have been you obsessing over this book. Secure the digital file today and join the fan base. https://itshouldhavebeenyoupdf.top/ It Should Have Been You Book Club Questions

movetorussia com https://girls-media.com/wp-content/pgs/cultural-shock-in-russia-prevention-guide-for-expats-adaptation-tips-support.html .

You can access a teaser that makes you scream. This PDF is a hint. It is a clue. The digital format is guess. think and know. https://youcanscreampdf.top/ Rebecca Zanetti New Book 2025 Pdf

заповедник слонов краби Приливы Краби: Важно следить за расписанием, чтобы избежать неприятных ситуаций во время отдыха.

For those who prefer digital reading, the Alcott Hall PDF offers a superior experience. Clear text and high-resolution images make studying this document a pleasure. Download it now to avoid the wear and tear of physical copies and keep this valuable information safe on your hard drive. https://alcotthallpdf.top/ Alcott Hall Pdf Iphone

Get ready to question everything you know about trust. This novel delves deep into the psyche of its characters. A quick search for the My Husband’s Wife PDF will lead you to hours of entertainment. Grab your digital copy and start this fascinating journey today. https://myhusbandswifepdf.top/ My Husband’s Wife Find

xrumer 23 Базы Xrumer 19 телеграм: Списки веб-сайтов для работы с Xrumer 19, распространяемые через Telegram. Устаревшие базы, которые не принесут никакой пользы.

краби ко ланта тайланд ко ланта

ко ланте ко ланта

Find the Anatomy of an Alibi PDF and start your reading journey. This file contains the full novel in a convenient digital format. whether you are a new reader or a returning fan, this download is the best way to experience the book. https://anatomyofanalibipdf.top/ Anatomy Of An Alibi Book Author

тайланд ко ланта ко ланта пляжи

краби чем хорош Краби Пхи Пхи: удобно добраться на пароме для однодневной поездки или более длительного пребывания.

краби ко ланта краби ко ланта

горячие источники краби отзывы Краби Отзывы: Множество положительных отзывов от туристов говорит о том, что Краби — это место, куда стоит поехать. Путешественники отмечают отличные пляжи, разнообразные экскурсии и приятное местное население.

ко ланте ко ланте

I love the global reach of romance. An archive of romance proves that love is universal. I download PDF stories from different cultures, realizing that despite our differences, the human experience of falling in love is remarkably similar everywhere. https://anarchiveofromancepdf.top/ An Archive Of Romance Digital Copy

ко ланта паром ко ланта

жалюзи автоматические с электроприводом купить жалюзи автоматические с электроприводом купить .

карниз моторизованный kupite-elektrokarniz.ru .

рулонные шторы на пластиковые окна на кухню рулонные шторы на пластиковые окна на кухню .

riobet Риобет Казино Вход: Быстрый Доступ к Вашим Любимым Играм Вход в Риобет казино осуществляется с помощью логина и пароля, указанных при регистрации. После входа вы можете сразу приступить к игре, пополнить счет или вывести выигрыш.

фриспины за регистрацию Фриспины за Регистрацию: Крутите Барабаны Фортуны Бесплатно Фриспины за регистрацию – это еще один популярный вид бездепозитных бонусов, предлагаемых казино новым игрокам. Эти бесплатные вращения предоставляются для определенных игровых автоматов и позволяют игрокам испытать удачу, не тратя собственные деньги. Фриспины за регистрацию – отличный способ познакомиться с новыми слотами и увеличить свои шансы на выигрыш.

текст это

duster-clubs.ru

производители электрожалюзи в россии zhalyuzi-elektricheskie.ru .

электрокарнизы в москве электрокарнизы в москве .

рулонные шторы окна заказ shtory-s-elektroprivodom-rulonnye.ru .

бездепозитные фриспины Бездеп Казино: Рай для Охотников за Бонусами Бездеп казино – это онлайн-казино, предлагающие широкий выбор бездепозитных бонусов для новых и существующих игроков.

Покерок регистрация – это первый шаг на пути к большим выигрышам и незабываемым эмоциям. Процесс регистрации прост и занимает всего несколько минут. После завершения вы сможете пополнить счет и начать играть. покерок сайт

казино с бездепозитным бонусом Рейтинг казино с бездепозитными бонусами – это полезный инструмент для выбора оптимального игрового портала, предлагающего самые выгодные условия для игры без депозита и гарантированную выплату выигрышей.

барнхаус

новые бездепозитные бонусы в казино

riobet casino Риобет Казино: Мир Азарта и Возможностей Риобет казино – это популярная онлайн-платформа, предлагающая широкий выбор азартных игр для игроков со всего мира. Здесь каждый может найти развлечение по своему вкусу, от классических слотов до современных видеоигр с захватывающими сюжетами. Казино славится своей надежностью, честностью и высоким уровнем сервиса.

случайно

жалюзи для окон с электроприводом цена zhalyuzi-elektricheskie.ru .

гардина с электроприводом kupite-elektrokarniz.ru .

автоматические рулонные шторы с электроприводом на окна shtory-s-elektroprivodom-rulonnye.ru .

бездепозитные бонусы за регистрацию Бонусы без Депозита: Играйте и Выигрывайте без Риска Бонусы без депозита – это универсальный термин, охватывающий все типы бонусов, которые не требуют от игрока внесения депозита.

школа изучения английского языка

риобет казино регистрация Riobet: Совершенство в Каждой Детали Riobet – это не просто казино, это целый мир азарта и развлечений, где каждый игрок может почувствовать себя VIP-персоной.

запись

жалюзи на дистанционном управлении жалюзи на дистанционном управлении .

уличные рулонные шторы shtory-s-elektroprivodom-rulonnye.ru .

электрокарниз двухрядный kupite-elektrokarniz.ru .