Plasma Arc Machining(PAM)

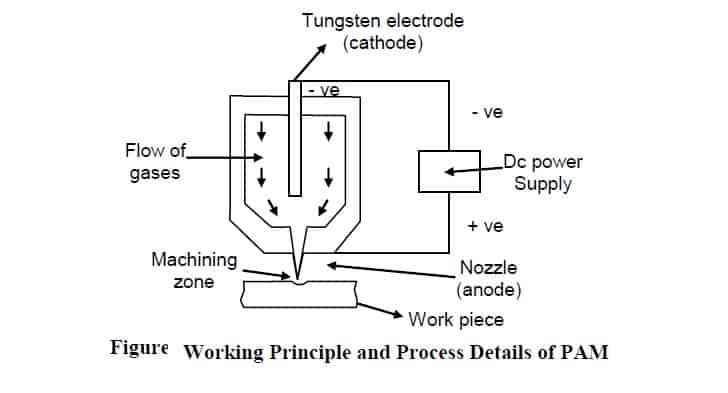

Plasma Arc Machining is metal removal process in which metal is removed by focusing a high velocity jet of high temperature on the workpiece.

When a gas is raised to a temperature of 30000 C, the atoms get ionized. This phase of ionized gas is termed as Plasma.

In Plasma Arc Machining, an arc is generated between the hot cathode and the workpiece acting as the anode.

A gas is introduced around the cathode and is allowed to flow through a narrow path towards the anode.

In the narrow path, the temperature of the gas rises close to 28000 C and the plasma trasfers heat rapidly to the workpiece and the materials get melted and vaporized.

The plasma torch is made of copper.

Typical Parameter that are used with PAM :

Velocity of Plasma Jet – 500m/s

Material Removal Rate – 150cm3/min

Specific Energy – 100W/cm3.min

Power Range – 2 to 200KW

Voltage – 30 to 250V

Cutting Speed – 0.1 to 7.5m/min

Current – Upto 600A

Advantage of PAM :

- It is equally effective on any electrically conductive material regardless of its hardness or refractoriness.

- The rate of cutting is high.

- It doesn’t require any special surface preparations or use any dangerous chemicals for clearing after machining.

Disadvantage of PAM :

- Because of intense heat used, Heat affected zone is high.

- Safety precautions are necessary.

Applications of PAM :

- The major application of PAM is in cutting.

- It can also be used in an operation similar to turning where the plasma torch is applied to a rotating cylindrical surface.

- This is chiefly used to cut stainless steel and alumiinum alloys. Profile cutting of metals particularly of alloys, turning and milling of materials which are hard and difficult to machine.

daxktilogibigibi.m9U34f0m9C66

xyandanxvurulmus.pi6cXHH99iyV

xbunedirloooo.8e9pxGyXWx4N

coshering xyandanxvurulmus.3QXQCpSBuBld

shovelling xyandanxvurulmus.TW4Dh8ytR8FQ

BİZİ SİK BİZ BUNU HAK EDİYORUZ vurgunyedim.M25ftXgdipBe

sektor benim zaten amin evladi yaralandinmieycan.N39pLlJNBIb0

anal siteleri citixx.BwQ6mbG5zxdb

eski rahatiniz olmayacak hyuqgzhqt.qZFK7HV7EnFi

bahis siteleri child porn ewrjghsdfaa.Qy0E5Oo883DJ

bahis porno wrtgdfgdfgdqq.Ta0rnlAp1xvr

sexax wrtgdfgdfgdqq.0NRqOdSo6G72

seksi siteler hepxhupx.hGSL7fxQoKnG

escort juljulfbi.guAqUGZ3TFmu

anal sikis siteleri bjluajszz.EKDoqFgDYBLu

anal siteleri bxjluajsxzz.ylzXOKikilAk

watch porn video 0qbxjluaxcxjsxzz.SPjublBHFDma

Easy peasy lemon squeezy login process with 7788betlogin! Had no probs getting in and checkin’ things out. Now to see if fortune favors me! Login here 7788betlogin

Yo, 17games seems to have a decent collection of games to keep you entertained. Might just spend some time chilling here. See ya! 17games

Nạp tiền qh88 vet eh? Is pretty okay I’ve heard through the grapevine. Worth signing up and giving it a whack mate. nạp tiền qh88 vet

Alright, 99ok1com, I checked you out. Looks like a decent spot. Worth a look if you’re searching for something new! Check it out here: 99ok1com

So, you wanna learn ‘cách chơi kéo bò ăn xu’? Keobovn.com seems like it might have some tips and tricks. Worth a shot! Here’s the link: cách chơi kéo bò ăn xu