Heat Engine, Classification of Heat Engine and Its Component

Engine:

An engine is a device which transform one form of energy into another form of energy. However, transforming the energy from one form to another, the efficiency of conversion plays an important role. Most of the engine converts thermal energy into mechanical work and therefore they are called Heat Engine.

Heat Engine is a device which transforms the chemical energy of a fuel into thermal energy and utilizes this thermal energy to perform useful work. Thus, thermal energy is converted into mechanical energy in a heat engine.

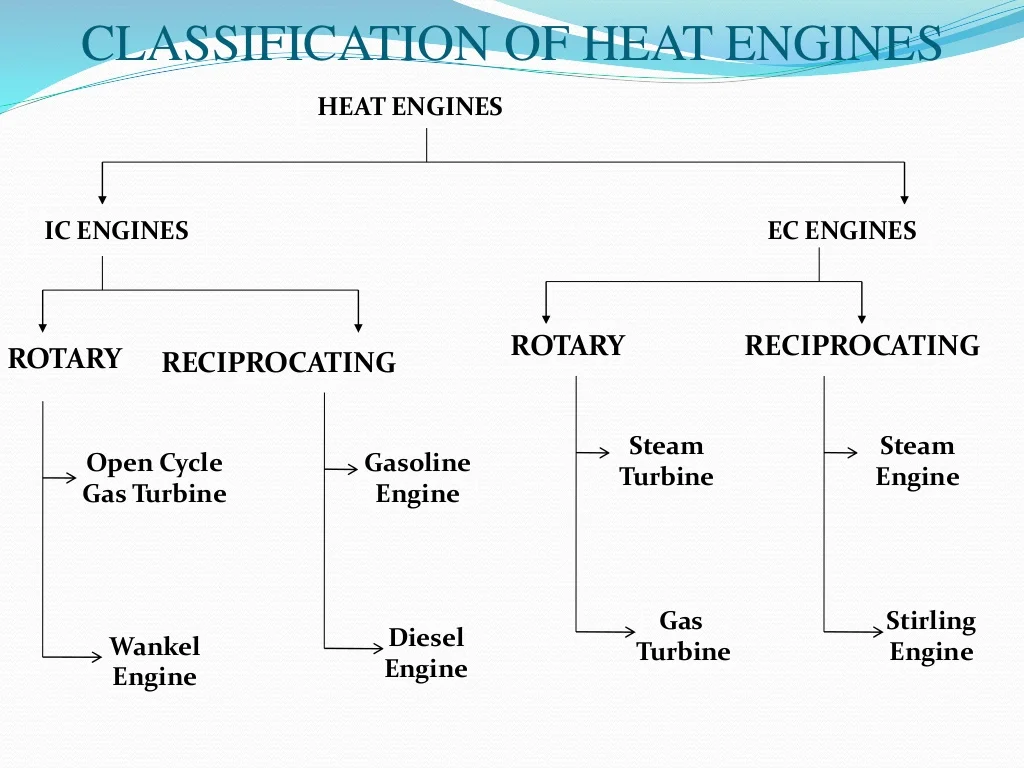

Heat engine can be broadly classified into two categories:

- Internal Combustion Engine(IC Engine)

- External Combustion Engine(EC Engine)

1. Internal Combustion Engine:

Those engine in which combustion takes place within the engine are known as Internal Combustion Engine.

Example: In a steam engine or steam turbine the heat is generated due to the combustion of fuel is employed to generate high pressure steam which is used as the working fluid in a reciprocating engine or a turbine.

2. External Combustion Engine:

Those engine in which combustion takes place outside the engine are known as External Combustion Engine.

Example: In case of gasoline or diesel engine, the product of combustion generated by the combustion of fuel and air within the cylinder form working fluid.

Heat Engine Components And Nomenclature

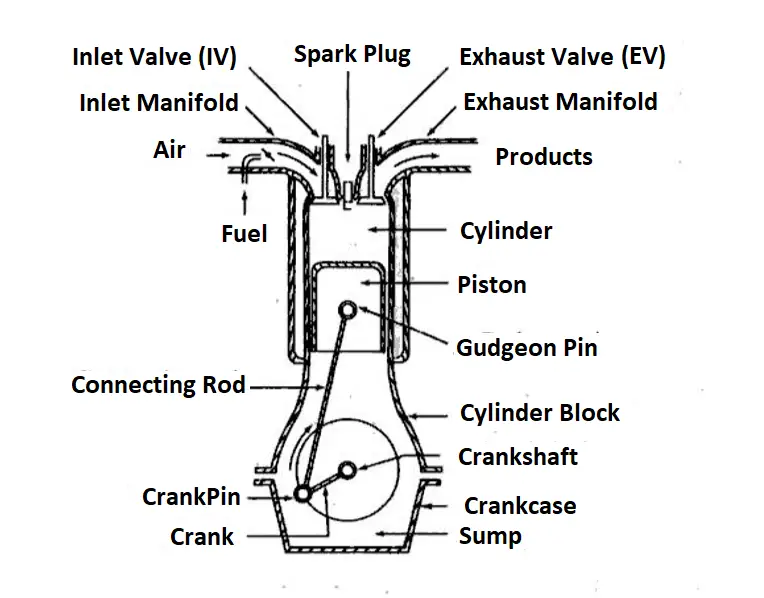

1). Cylinder Block:

- The cylinder block is the main supporting structure for the various components.

- The cylinder of multicylinder engine are cast as a single unit, called Cylinder Block.

- The cylinder head and cylinder block are provided with water jackets in the case of water cooling or with cooling fins in the case of air cooling.

- Cylinder head gasket is incorporated between the cylinder block and cylinder head.

- The cylinder head is held tight to the cylinder block by number of bolts or studs. The bottom position of the cylinder block is called Crankcase.

2). Cylinder:

- As the name implies it is a cylindrical vessel or space in which piston makes a reciprocating motion.

- The varying volume created in the cylinder during the operation of the engine is filled with the working fluid and subjected to different thermodynamic processes.

- The cylinder is supported in cylinder block.

3). Piston:

- It is a cylindrical component fitted into the cylinder forming the moving boundary of the combustion system.

- It fits perfectly(snugly) into the cylinder providing a gas-tight space with the piston rings and the lubricants.

- It forms the first link in transmitting the gas force to the output shaft.

4). Combustion Chamber:

- The space enclosed in the upper part of the cylinder, by the cylinder head and the piston top during combustion process, is called Combustion Chamber.

- The combustion of fuel and the consequent release of thermal energy results in the building up of pressure in this part of the cylinder.

5). Inlet Manifold:

- The pipe which connects the intake system to the inlet valve of the engine and through which air or air fuel mixture is drawn into the cylinder is called Inlet Manifold.

6). Exhaust Manifold:

- The pipe which connects the exhaust system to the exhaust valve of the engine and through which the products of combustion escape into the atmosphere is called Exhaust Manifold.

7). Inlet and Exhaust Valve:

- Valves are commonly mushroom shaped poppet type.

- They are provided either on the cylinder head or on the side of the cylinder for regulating the charge coming into the cylinder(inlet valve) and for discharging the product of combustion(exhaust valve) from the cylinder.

8). Spark Plug:

- It is a component to initiate the combustion process in Spark Ignition(SI) Engine and is usually located on the cylinder head.

9). Connecting Rod:

- It interconnects the piston and the crank shaft and transmits the gas forces from the piston to the crankshaft.

- The two ends of connecting rod are called as the small end and the big end.

- The small end is connected to the piston and by gudgeon pin and the big end is connected to the crankshaft by crankpin.

10). Piston Rings:

- Piston Rings are fitted into the slot around the piston, provide a tight seal between the piston and the cylinder wall, thus preventing leakage of the combustion gases.

11). Crankshaft:

- It converts the reciprocating motion of the piston into useful rotary motion of the output shaft.

- In the crankshaft of a single cylinder engine, there are pairs of crank arms and balanced weights.

- The balance weights are provided static and dynamic balancing of the rotating system.

- The crankshaft is enclosed in a crankcase.

12). Gudgeon Pin:

- It forms the link between the small end of connecting rod and piston.

13). Camshaft:

- The camshaft and its associated parts control the opening and closing of the two valves.

- The associated parts are push rods, rocker arms, valve springs and tappets. This shaft also provides the drive to the ignition system.

- The camshaft is driven by the crankshaft through timing gears.

14). Cams:

- These are made as integral parts of the crankshaft and are designed in such a way to open the valves at the correct timing and to keep them open for the necessary duration.

15). Flywheel:

- The net torque imparted to the crankshaft during one complete cycle of operation of the engine energy fluctuates causing a change in the angular velocity of the shaft.

- In order to achieve a uniform torque an inertia mass in the form of a wheel is attached to the output shaft and this wheel is called the Flywheel.

- Laser Beam Machining(LBM)

- Automation And Types of Automation in Manufacturing

- Numerical Control(NC) and Computer Numerical Control(CNC)

- Plasma Arc Machining(PAM)

- Heat Engine, Classification of Heat Engine and Its Component

Right, 5555bet2… I’d say it’s not bad. Decently laid out and not too complicated. Could be worth a punt! Just keep a handle on your spending, yeah? 5555bet2

Win3799 is where it’s at for some chill gaming. Nothing too intense, just good times. Definitely recommend for a relaxed evening win3799.

24BettingAviator? Alright, buckle up for some Aviator action! It’s pretty good, easy to use, and feels fair. Give 24bettingaviator a try!

51GameLogin is a quick and easy way to get into the games, good navigation helps find the right game. I found this very positive: 51gamelogin.

Mwmbetapp is pretty cool! I mean, it does what it needs to do. I had some issues on the old version but theyve fixed them. Gotta give it a go mwmbetapp.

MXFun es lo máximo. Me encanta la variedad de juegos y la plataforma es súper fácil de usar. ¡Siempre me divierto un montón! Give it a try! mxfun

WinonaCasinoOnline es mi lugar favorito para relajarse y ganar dinero al mismo tiempo. La interfaz es amigable y los juegos nunca aburren. I recommend here. winonacasinoonline

Fun88mx1 es donde encuentro la mejor acción. Siempre hay algo emocionante pasando y los premios son bastante buenos. Si buscas un lugar con mucha adrenalina, visita fun88mx1.

CN3789. Okay, I’m intrigued now. Hopefully, it’s something unique and not just a clone of the million others out there. Time to investigate! cn3789

Heads up, bettors! If you’re looking for a smooth login experience to oleybet, oleybetlogin looks like the spot to go. No more hassle, hopefully! Go take a peek: oleybetlogin

Hello everyone! I thought I would share 52win123 with all of you. It has lots of different options and I am having fun with their games. Check it out right now: 52win123