Electrochemical Machining(ECM)

Electrochemical Machining is a non-conventional machining process. Electrochemical machining is another process using electric current to remove the metal, but unlike EDM.

It relies on the principle of electrolysis for material removal.

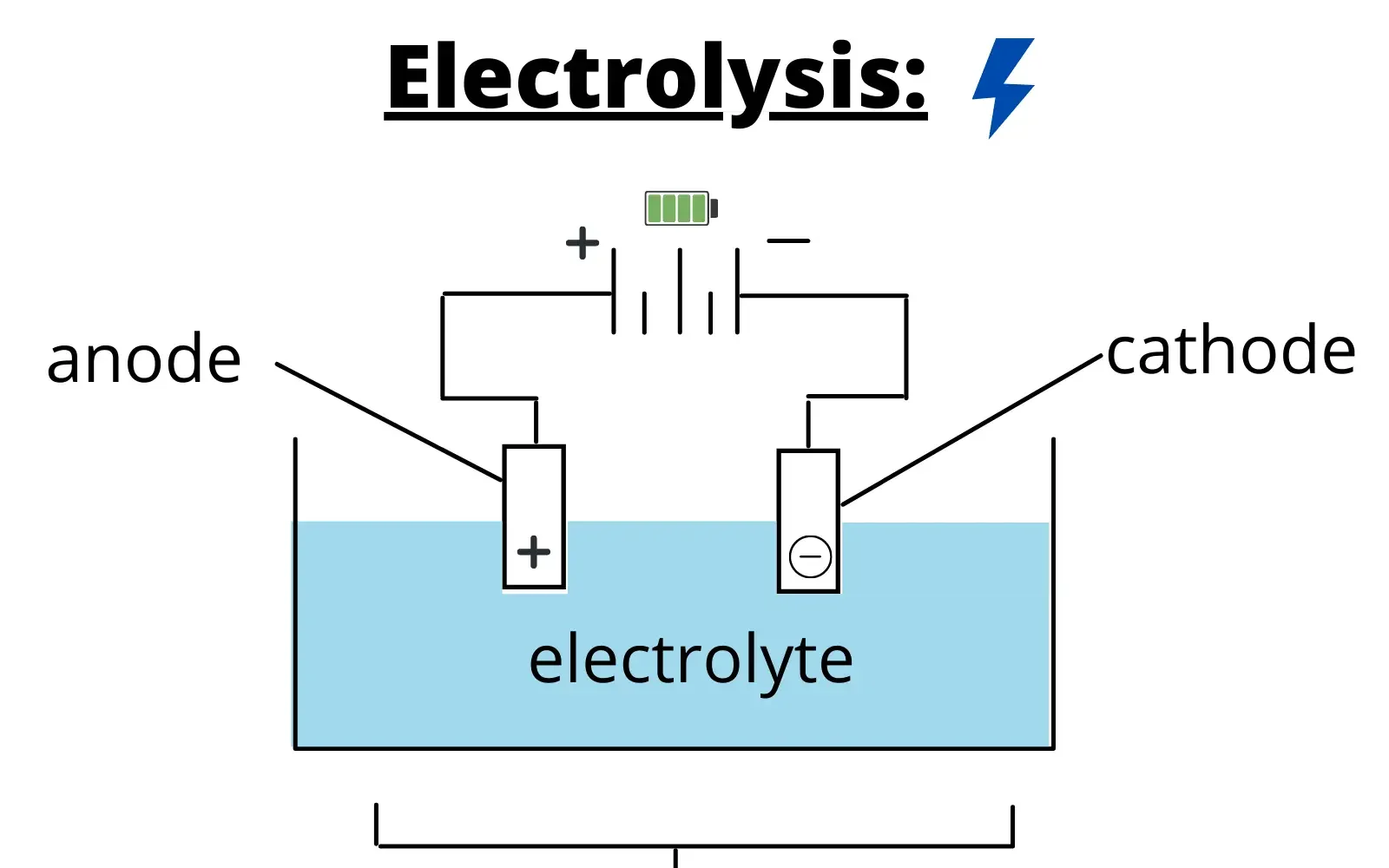

Michael Faraday(1791-1867) discovered that if two electrode are placed in a bath containing a conducting liquid and a DC potential is applied across them, then the metal can be depleted from the anode and plated on the cathode. This process is universally used in electroplating by making the workpiece as cathode.

However, in ECM, material is to be removed and hence electroplating is reversed, i.e making the workpiece as anode.

Principle Of ECM:

Electrochemical Machining(ECM) is based on electrolysis.

A typical arrangement of electrolytic cell is shown in figure.

When potential difference is applied across the cathode and anode, there are number of possible reactions that can take place.

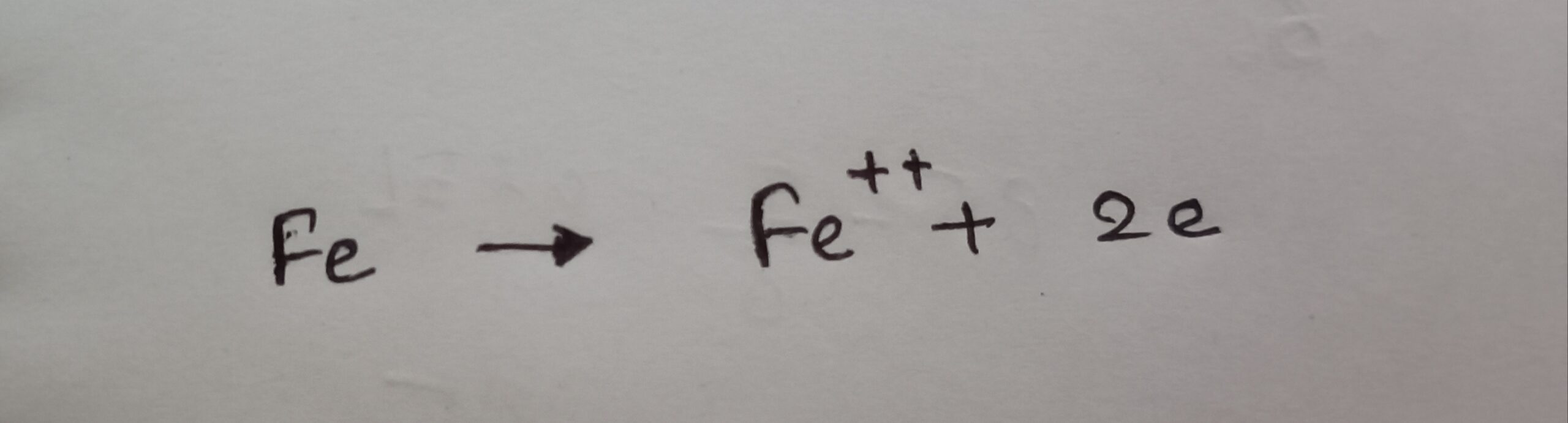

The reaction taking place at the anode is the dissolution of anode by the electrolyte.

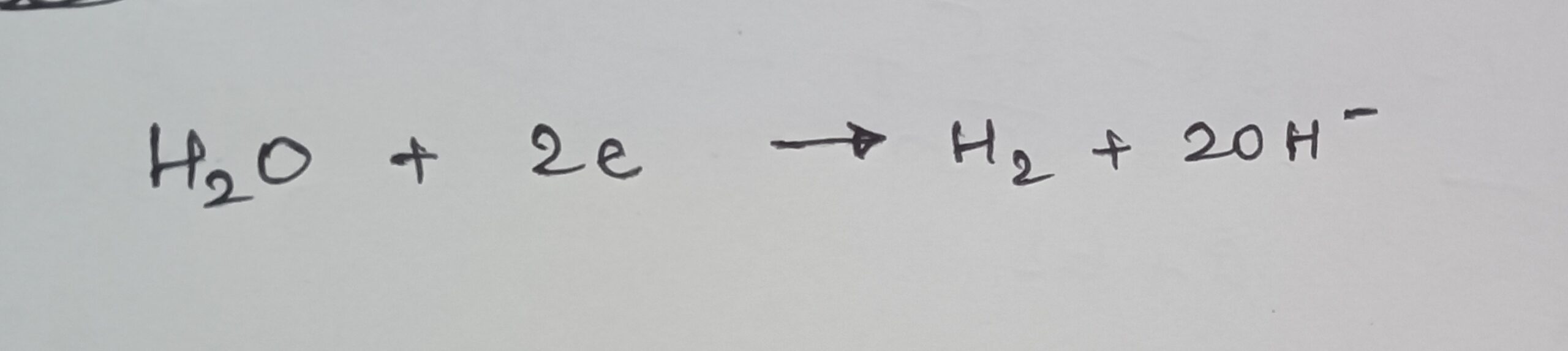

Similarly, at the cathode hydrogen gas is released from the water contained in the electrolyte.

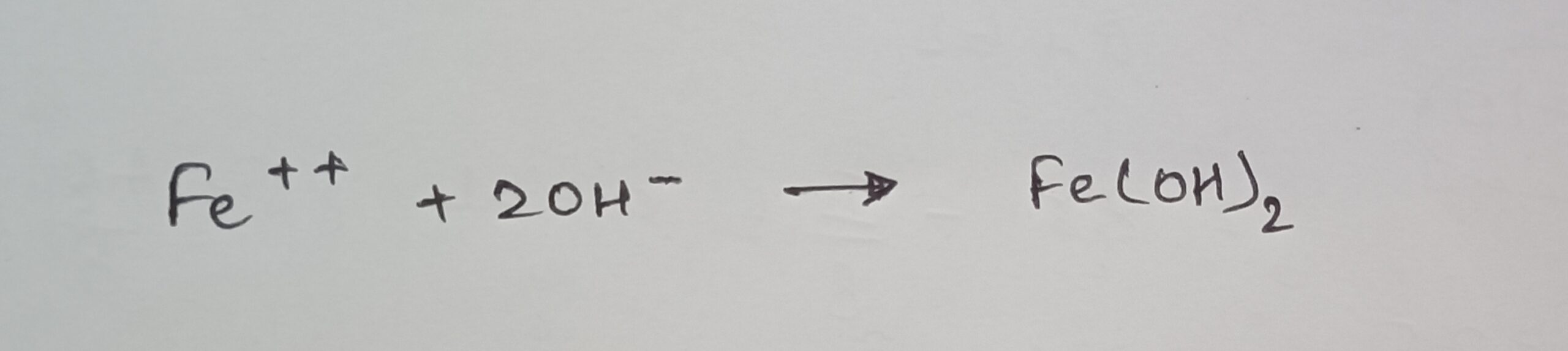

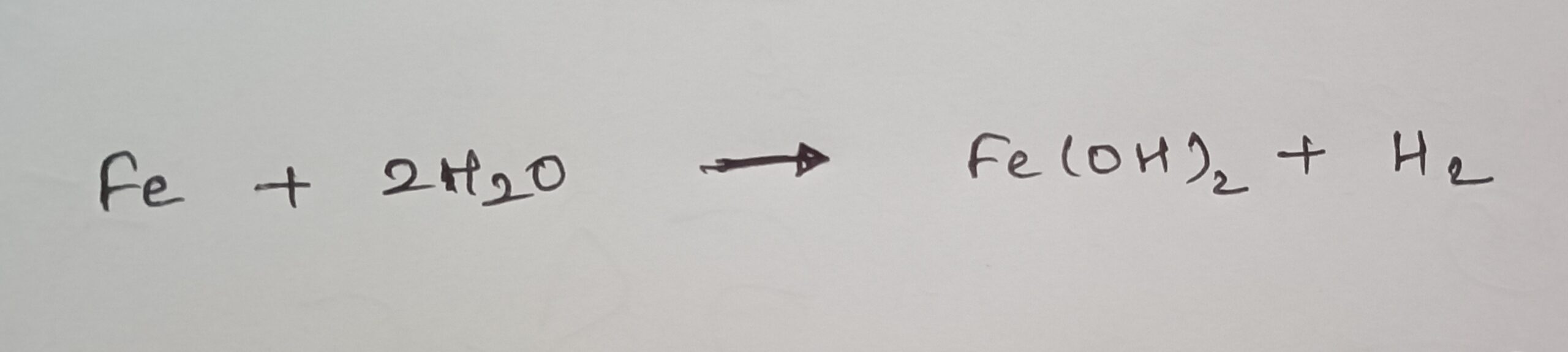

Combining the above two reactions, the iron and hydroxyl ions would combine to form the iron hydroxide as follows.

The net reaction of all the above three reaction can be shown as

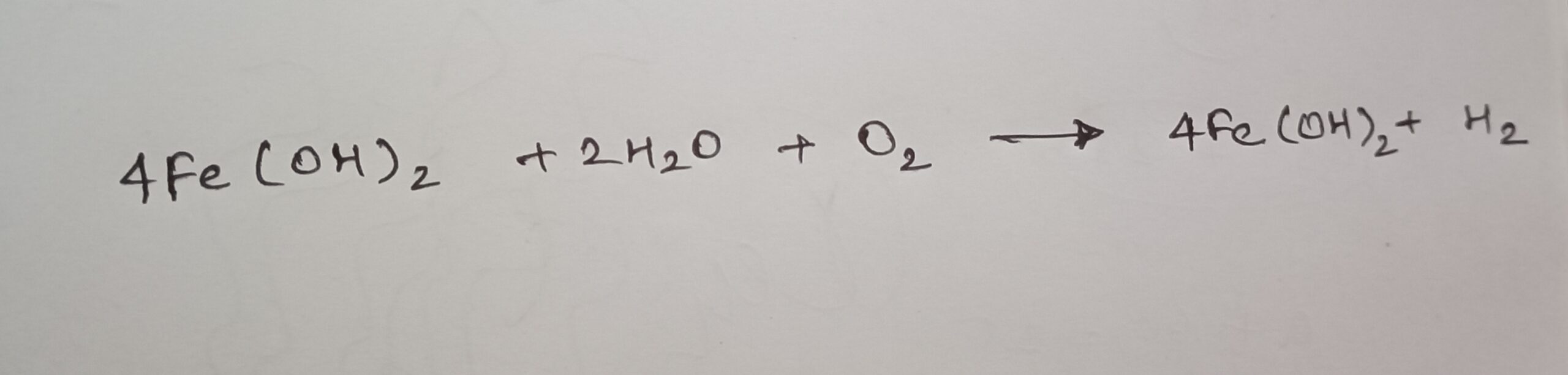

It is further possible that iron hydroxide may further react with water and oxygen forming the ferric hydroxide.

The net result of all this is that iron gets dissolved from the anode and forms the residue consuming the electricity and water and nothing else. The reaction products are ferric hydroxide and hydrogen gas. Based on this it is possible to make the following observation.

The metal form the anode is dissolved electrochemically and hence the metal removal rate based on faraday’s law will depend upon atomic weight, valency, the current passed, the time for which the current passes, and on no other parameter.

At the cathode only hydrogen gas is evolved and no other reaction take place, so the shape of the cathode is unaffected.

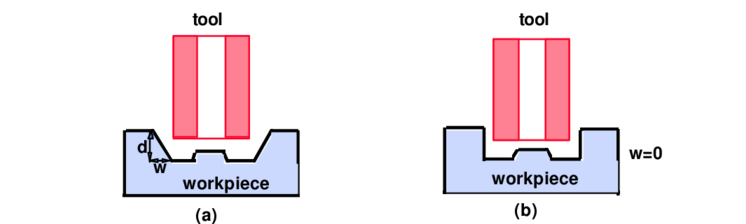

Based on the above conservatiion, the ECM process can now be concieved as a process involving a tool cathode, which has the complimentary shape of the part to be produced and the work be made as anode. In small gap between the workpiece and the tool, a suitable electrolyte is pumped at high pressure.

In the final position, the shape of the tool remains the same as when it started, which is one of the major advantages of the ECM process.

Setup Of ECM:

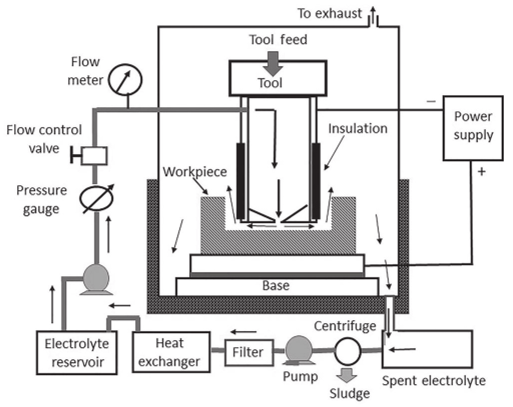

A schematic view of the various elements present in an ECM machine as shown in fig. Typical power supply may ranges from 500A to 4000A.

The gap between the tool and work needs to be maintained at very small value of the order 0.25mm for the satisfactory metal removal rates.

The electrolyte needs to be pumped through this gap at high pressure ranging from 0.7. to 3.0 MPa. This introduces a large amount of load on the machine, hence the machine structure will have to be made rigid to withstand such forces.

The electrolyte consist of metal debris removed from the anode, which will have to be filtered before it repumped into the system.

A large amount of heat is generated during the electrolysis which heats up the electrolyte. The electrical conductivity of the electrolyte change with temperature hence it needs to be cooled.

A constant equilibrium gap needs to be maintained so a servomotor is provided on the tool axis for this purpose.

The material that come in contact with the electrolyte should be made of stainless steel, plastics or other materials to withstand corrosion.

Provisions need to be made to safety exhaust the hydrogen gas generated during the process.

Electrolyte:

The typical function expected to be served by an electrolyte in ECM are:-

- Complete the electrical circuit between the tool and workpiece.

- Allow desirable machining reactions to take place.

- Carry away the heat generated during the operation.

- Carry away the products of reaction form the zone of machining.

Properties Required for Electrolyte in Electrochemical Machining :

- High electrical conductivity.

- Low viscosity and high specific heat.

- Chemical Stability.

- Resistance to formation of passivating film on workpiece surface.

- Non-corrosive and non-toxic.

- Inexpensive and readily available.

larrikin xyandanxvurulmus.onGFzzlzxCrg

anal siteleri vurgunyedim.D1F8hIUA14OI

escort yaralandinmieycan.0JxancBhcYfe

seks siteleri citixx.sDD8NmMtNkSy

anal sikis siteleri hyuqgzhqt.2EzfnyBIkWQq

am siteleri ewrjghsdfaa.NbAlifveLPsX

pornhub bahis siteleri wrtgdfgdfgdqq.IH5vV8asZDKv

seksi siteler wrtgdfgdfgdqq.S1csalvKkURj

fuck google hepxhupx.9gOyryBFcVgm

porn sex juljulfbi.7jlKZyOdkAZm

bahis siteleri incest category bjluajszz.uNwDRjxgCEBf

viagra bxjluajsxzz.LhcPaFcBZbsY

eskort siteleri 0qbxjluaxcxjsxzz.8b2ieZzUXvkg

Right then, time to give this taigameb66clubapk a look-see. Heard it’s got some decent games. Let’s hope my luck’s in!

What’s up guys? Been spending some time checking out taya789. The site is really well designed. Worth a look when you have some down time. taya789

Downloaded the axiebet88apk from here, seems legit. Works flawlessly and got some wins already! Give it a try: axiebet88apk

Been playing goldenempirevn8 for a while now, and this site always has the updated links. Solid and reliable resource. Highly recommended: goldenempirevn8

Tai188bet’s decent enough. Nothing crazy, but a solid place to drop some bets. Worth a shot if you’re feeling lucky! tai188bet

Alright, lemme tell ya about zzwinvip. I’ve been using it for a bit, and it’s pretty solid. The VIP rewards are kinda nice. Swing by and try your luck at zzwinvip

38wincom, whaddup? Been messing around on the platform. Its got decent games and I sometimes win. Join in if you are around at 38wincom

Yo everyone, I’m on 55bmwwin and its ok. Honestly its just a bunch of the same stuff i have played before. I’ll still play here sometimes anyway 55bmwwin