Electrical Discharge Machining(EDM)

EDM is a non-conventional machining process.

Principle :

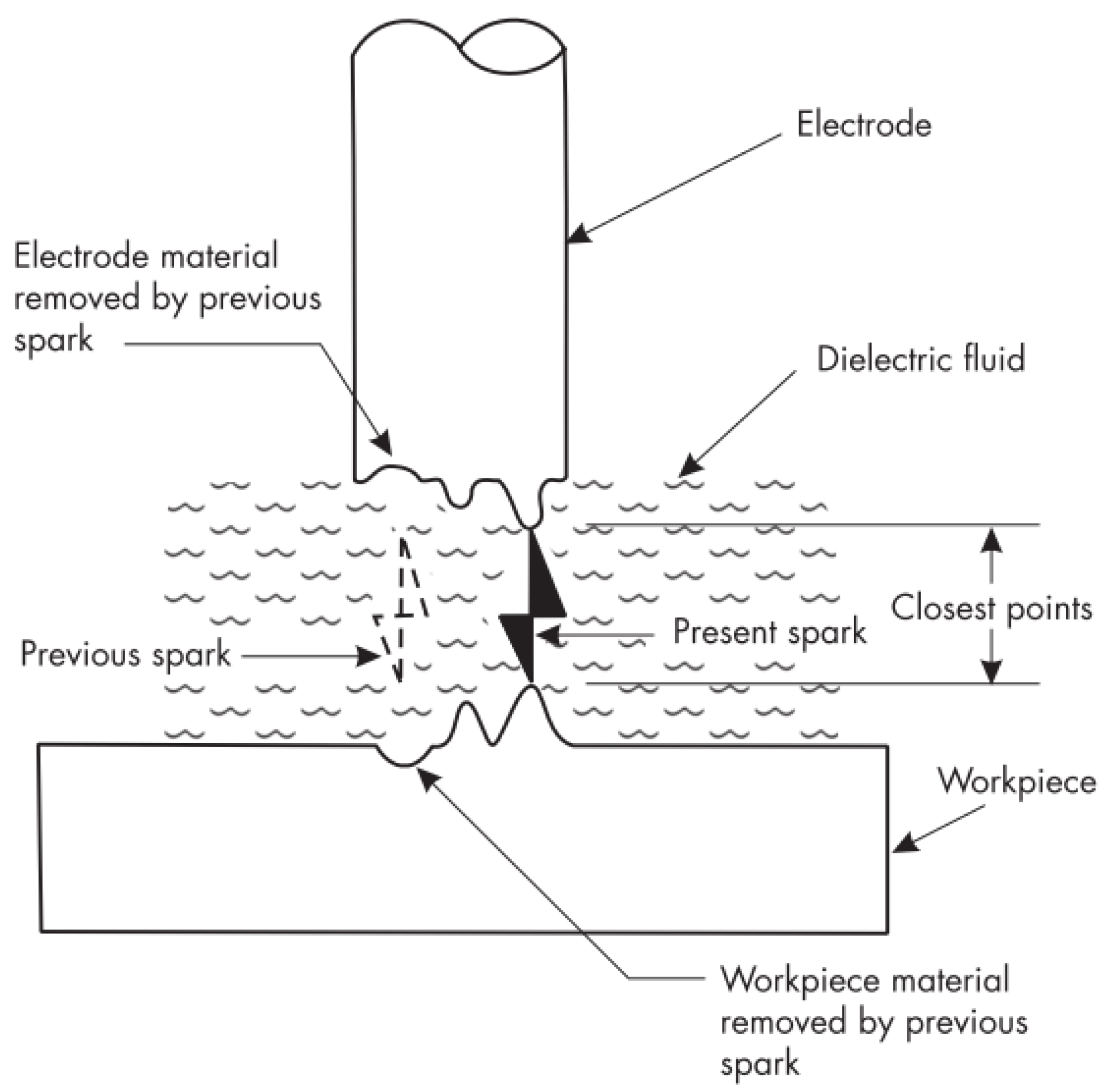

Electrical discharge machining involves a controlled erosion of electrical conductive material by the initiative of rapid and repetitive spark discharge between the tool and workpiece separated by a small gap of about 0.01 to 0.50 mm.

Thus spark gap is immersed in dielectric fluid.

The controlled pulsing of direct current between the tool and workpiece produces the spark discharge.

Initially, the gap between the tool and workpiece, which consist of dielectric fluid is not conductive. However, the fluid is ionized on the application of pulsed DC current.

It enables the spark discharge to pass between the tool and workpiece.

At any given time only one spark will be made between the tool and workpiece at the shortest path of least resistance.

The energy of the arc is so concentrated that it causes the electrode(tool) and workpiece to melt. But the tool material is so choosen that it melts less.

The metal and dielectric fluid is partly vaporised causing sudden expansion.

The blast from the expanding vapors knocks some molten particles loose, and the remaining molten metal hardens.

Setup of Electrical Discharge Machining :

The temperature of the arc may reach about 10000 degree Celsius.

The wear debris would carried away by dielectric fluid which is continuous circulation.

The same process as described above would be continued a number of times per second with each pulse removing a small wear particles from workpiece.

And thus causing the material to the shape of the electrode.

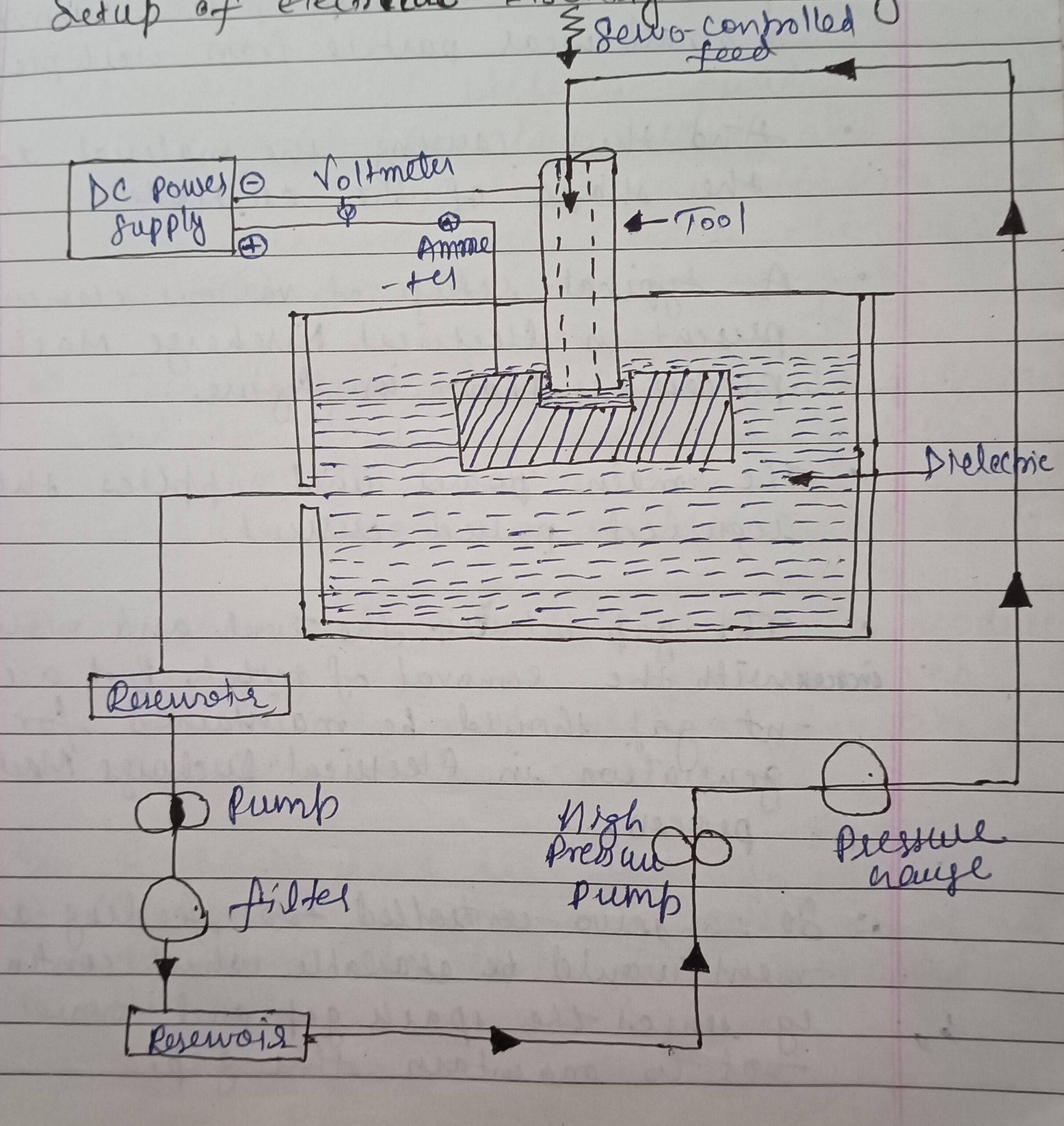

A typical setup of various element present in Electrical Discharge Machining process is shown in figure.

The main power unit supplies the required pulsed current.

The gap between the tool and workpiece increase with the removal of metal.

But a constant gap should be maintained for spark generation in Electrical Discharge Machining Process.

So, a servo-controlled tool feeding arrangement would be available which continuously senses the spark gap and moves the tool to maintain the gap.

Dielectric Fluid :

A dielectric fluid is a liquid whic has dielectric properties to act as an insulator at one time and to act as a conductor on another time.

It is a spark conductor, coolant and also a flushing medium.

Characteristics of Dielectric Fluid :

- It should have low viscosity and a good wetting capacity to provide effective cooling mechanisms and remove the debris particles from the machining gap.

- The dielectic fluid should have sufficient and stable dielectric strength to serve as insulator between the tool and workpiece till the breakdown voltage is reached.

- It should flush out the particles produces during the spark out of the gap. This is the most important function of dielectric fluid.

- It should have high fluidity.

- It should be chemically neutral, so as not to attack the tool, the workpiece and the tank.

- It’s flash point should be high to avoid any fire hazards.

- It is non-toxic.

- Economical and easily avalable.

Note :

- The ordinary water posses almost all these properties but since it causes rusting in the workpiece, so it is not used.

- The most commonly used types of fluid is petroleum oil, kerosene oil, liquid paraffin, and silicon oil are also used.

Tool/Electrode Material :

The selection of electrode material depends on the following :

- Material Removal Rate

- Wear Ratio

- Ease of shaping the electrode

- Cost

In EDM process, the shape of the electrode is impressed on the workpiece in its complementary form and such the shape and accuracy of the tool plays a very important role in the final accuracy of workpiece machined.

The electrode material should have following characteristics to serve as good tool :

- It should be conductor of electricity and heat.

- It should be easily machinable to any shape.

- It should produce efficient M.R.R from the workpiece.

- It should have low tool wear rate.

- It should available in variety of shapes.

The most commonly used tool materials are Brass, Copper, Graphite, Al-alloys, Copper-Tungsten Alloys and Silver-Tungsten Alloys.

Process Parameters :

The important process parameter in EDM process are :

1. Current in Each Spark :

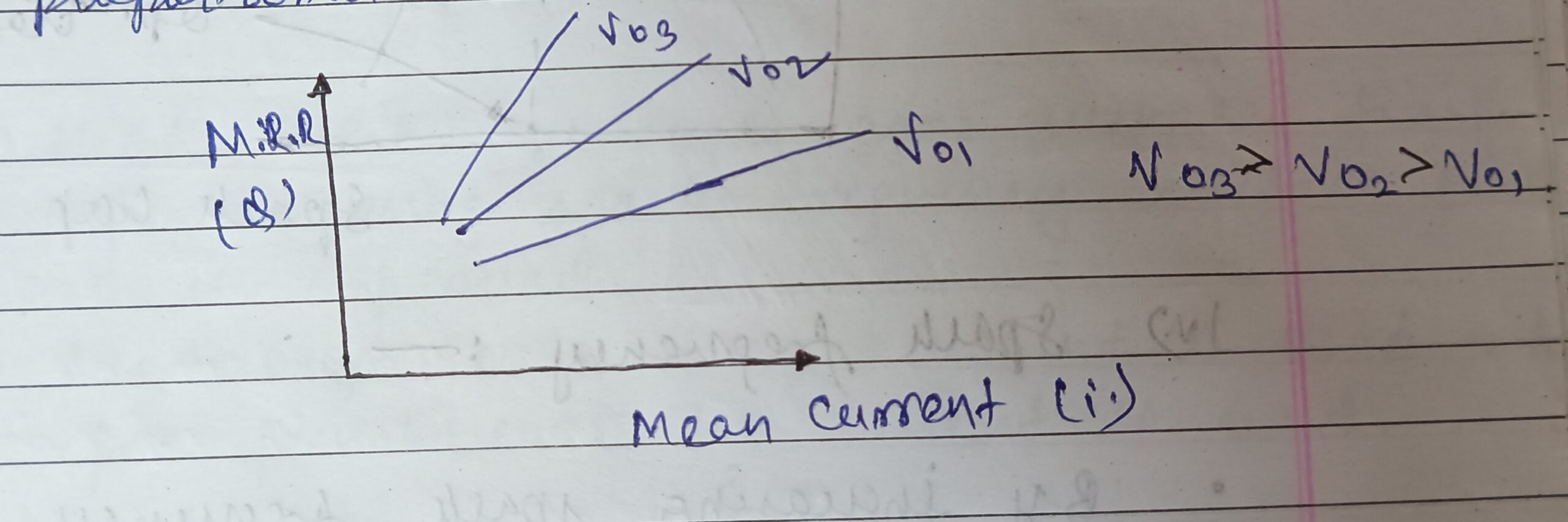

- The amount of material removed and the surface finish produced is dependent upon the current in each spark. The M.R.R is directly proportional to the current.

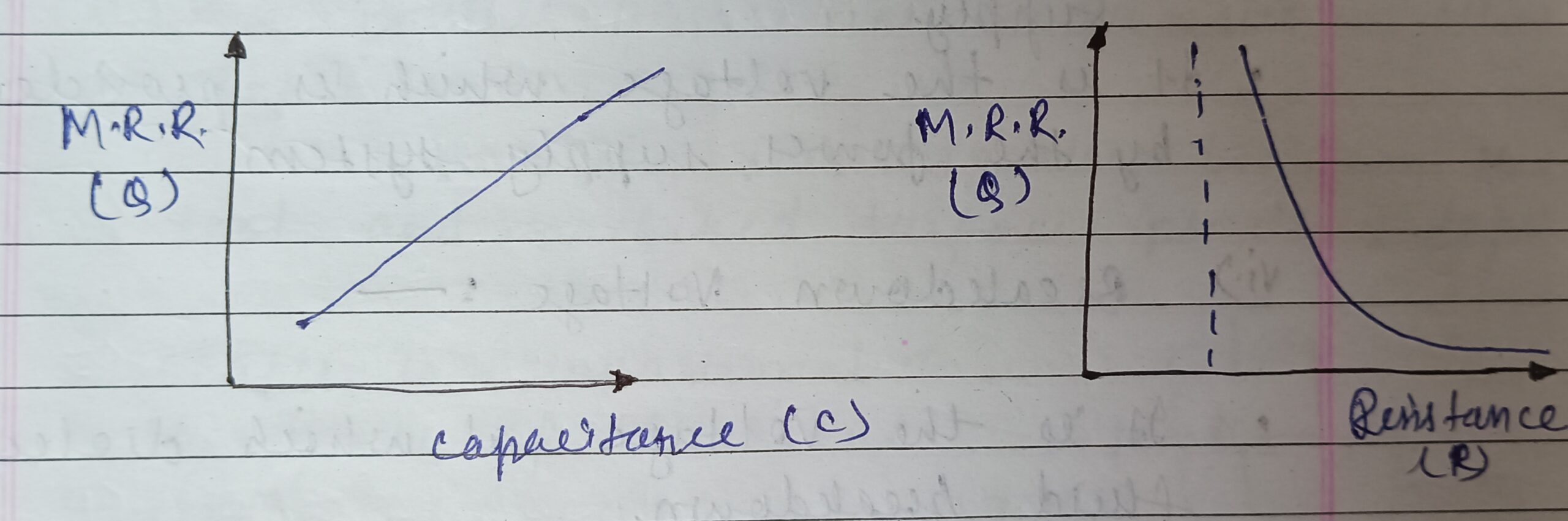

2. Resistance & Capacitance :

- Increase in capacitance will result in increase of M.R.R.

- Decrease in resistance will result in increase of M.R.R.

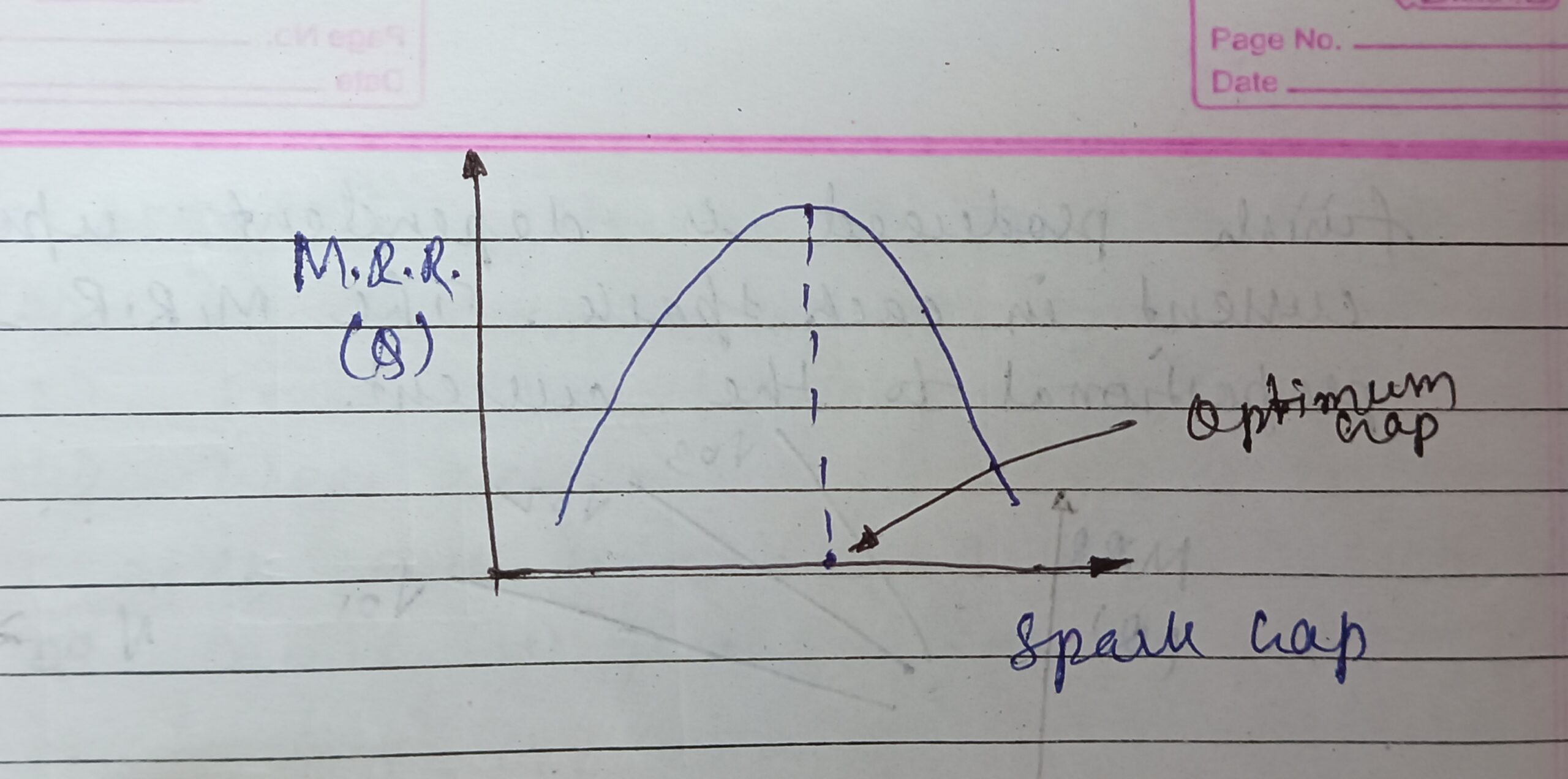

3. Spark Gap :

- Decrease in spark gap results in low M.R.R.

- This results in high accuracy and better surface finish.

4. Spark Frequency :

- By increasing the spark frequency surface finish is improved.

- It is about 1000 spark/revolution.

5. Supply Voltage :

- Its ranges between 50V to 400V DC supply.

- It is the voltage which is provided by the power supply system.

6. Breakdown Voltage :

- It is the voltage at which dielectric fluid breakdown.

- Increase in breakdown voltage results in increase of spark energy.

- So, M.R.R. increases but surface finish decreases.

Output Characteristics :

The ouput characteristics which are affected by the process parameter are :

1. Surface Finish :

- High M.R.R. produces poor surface finish.

- By increasing spark frequency surface finish is improved.

- For rough cuts heavy current is used and for finish cuts less current is used.

2. Accuracy :

- The side sparks affect the accuracy of the surface finish.

- By close control of several available a tolerance of +0.003 to -0.003 mm can be obtained.

- Two possible in accurance are shown below :

- Taper:

- The side sparks between the tool and machined surface produces taper.

- Taper is proportional to the square of the diameter of the tool

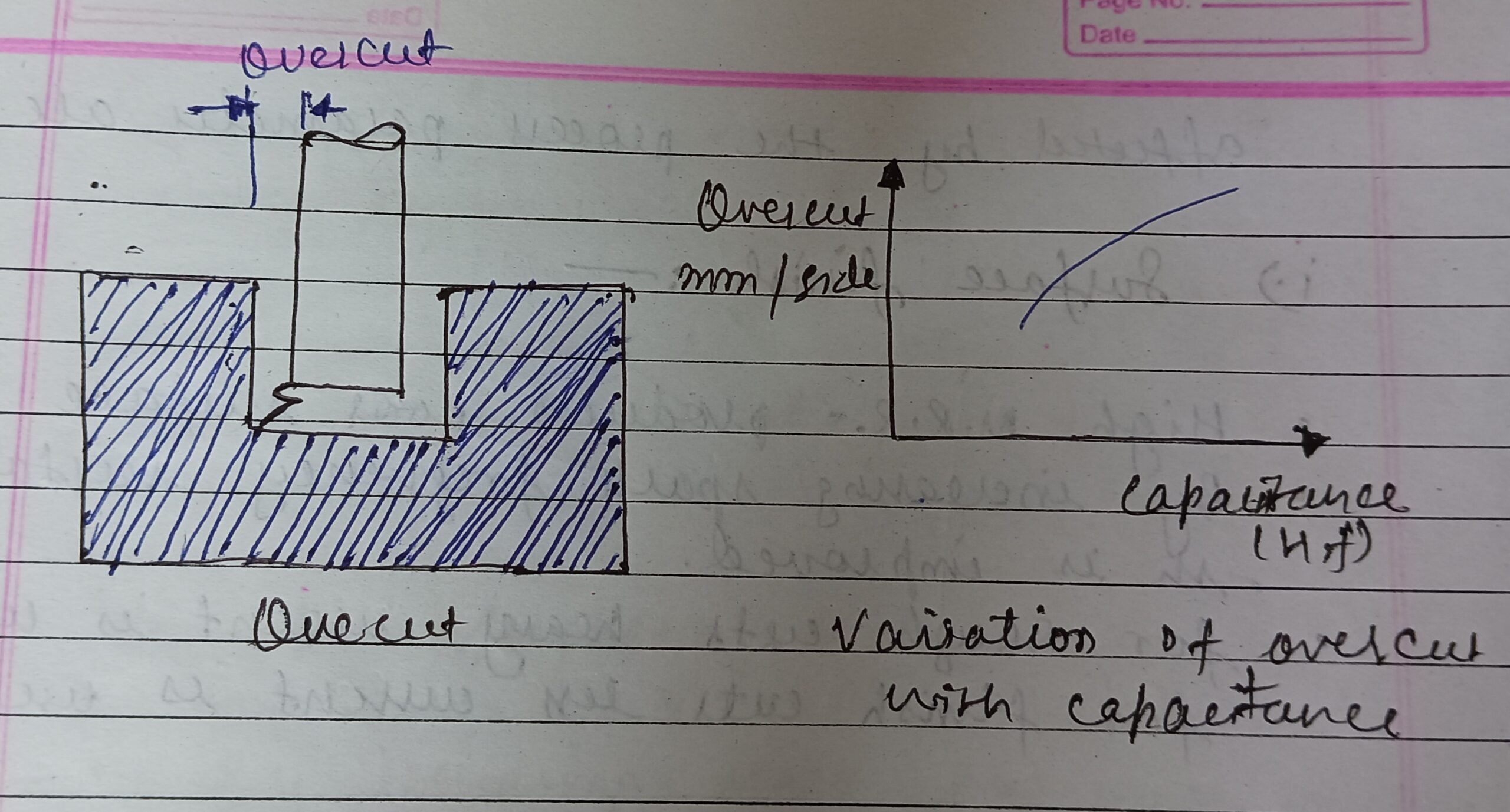

- Overcut

- Similarly overcut is produced by the spark side.

- Taper:

Advantages of EDM :

- Complicated shapes can be produced on workpiece.

- No stress is produced as there is no contact between tool and workpiece.

- Any material can be machined irrespective of their hardness.

- M.R.R are almost comparable with that of conventional machining process.

- Delicate workpiece can be machined.

Disadvantage of EDM :

- The workpiece should be electrically conductive to be machined by EDM process. Thus non-metallic such as plastics, ceramics or glass cannot be machined by EDM.

- It cannot produce very sharp corners.

- Power consumption is high.

- Wear rate of tool is considerably higher and also overcut is a serious problem.\

- M.R.R is quite low.

Application of EDM :

- EDM priocess can be used for microhole, drilling, curve hole drilling.

- EDM is particularly useful for internal cuts that are hard to get tool into.

- In EDM method, small holes about 0.13 mm in diameter and as deep as 20mm depth can be drilled. Due ton this EDM is particularly useful for machining of small holes, orifice in Diesel fuel Injection, Nozzle or in Aircraft Engine.

- Drilling of very small and high aspect ratio of the order of 30 is common example of EDM application.

- Milling EDM can be used to machine complex shapes with simple cylindrical electrode/tool.

daxktilogibigibi.JpS8RmumuWrB

xyandanxvurulmus.oKQKmJvDI6op

xbunedirloooo.tPLnQmfVztG6

courtlike xyandanxvurulmus.wQQNZB7zVrjZ

catarrh xyandanxvurulmus.G198ijmCj0Ws

anal sikis siteleri vurgunyedim.2i7enio6wtQe

viagra yaralandinmieycan.S14j3nqYAljb

viagra citixx.TCIbiaSUoOAU

viagra hyuqgzhqt.1zPMBAJyPP2O

sexx ewrjghsdfaa.7twewTmojkBE

BİZİ SİK BİZ BUNU HAK EDİYORUZ wrtgdfgdfgdqq.W3mmTInq84wS

bahis siteleri sikis wrtgdfgdfgdqq.o7kfM1y6FTL1

seks siteleri hepxhupx.9SQZmHPzb2qA

eskort siteleri juljulfbi.BK0klZsUMdvA

amciik siteleri bjluajszz.ITriBjbXzAaV

bahis siteleri porn sex incest bxjluajsxzz.zfyTQmHjE3FU

escort siteleri 0qbxjluaxcxjsxzz.fNG2HatC1uee

Just downloaded mubetapp and gave it a whirl. The interface is clean and easy to navigate, which is a big win for me. Found some decent odds and placed a few bets. So far, so good! Give it a shot and let me know what you think! Check it out: mubetapp.

Hey, if anyone is looking for a new gaming site to check out, I recommend pakwin777. I’ve been playing there for awhile, and the game selection is awesome.pakwin777

F188, heard you’re in the game. Is the platform smooth? Mobile-friendly? Don’t want any lag ruining my winning streak! Thanks in advance. f188

Vipph77 dude, I’ve been playing there! Solid platform, easy to use, and the payouts are pretty quick. Give it a shot! Check it out –> vipph77

Jilibetapplogin is my jam! Easy to login from my phone, games run smooth, zero lag. Give it a try bros, you won’t regret it ! Login here –> jilibetapplogin

4twingame es una opción divertida para pasar el rato. Lo recomiendo si buscan algo diferente y con buenos gráficos. Échale un vistazo a 4twingame.

Alright guys, been messing around on pk92game for a bit now. Honestly, it’s pretty decent! The games are fun and the site’s easy to navigate. Give pk92game a whirl!

Alright everyone, pk11 isn’t too bad. A few fun games here and there. Worth a shot. Go visit pk11.

Pagolbete’s got some decent odds, man. Put a few bucks down and see what happens. Worth a look if you’re hunting for a new place to bet. Ready to give it a shot? pagolbete

RS88com—not bad, not bad at all. Lots of action going on. Navigation could be a bit smoother but overall, solid. Give it a whirl! Find out more: rs88com

JL588 has a decent selection of slots if that’s your thing. Pretty straightforward to use. Nothing mind-blowing, but reliable. Want to play? jl588