Abrasive Water Jet Machining (AWJM)

In Abrasive Water Jet Machining(AWJM), the water jet contains abrasive particles(such as Silicon Carbide or Aluminium Oxide)which increase the material removal rate about that of water jet machining.

It is an Advanced Water Jet Machining Process that includes Abrasives as a medium.

To overcome the disadvantage of water jet machining, the abrasive particles will be added into the water so that the abrasive particles along with water also come out from the nozzle at a very high velocity to remove the material from the surface of a workpiece to get desired shape and size at high accuracy.

Metallic, Non-metallic and advanced composite material of various thickness can be cut.

The process is suitable particularly for heat sensitive material that cannot be machined by process in which heat is produced.

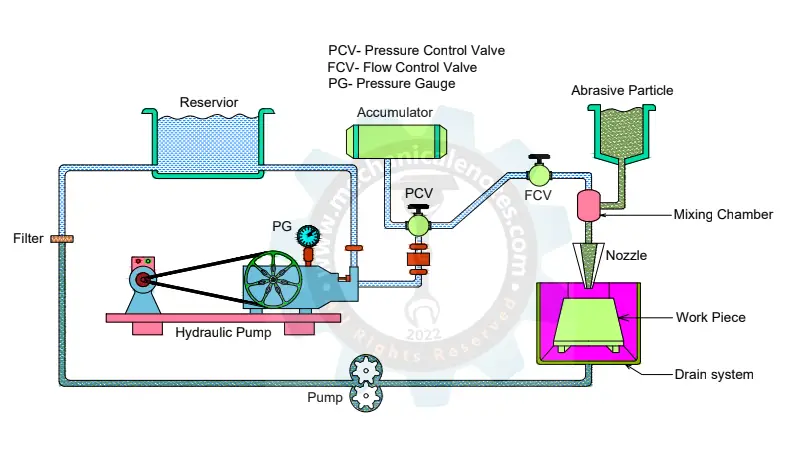

Main Components of Abrasive Water Jet Machining(AWJM) :

The main parts of the Abrasive Water jet Machining Process are as follows :

Reservoir:

- The reservoir will act as a basic part for storing water and this water is sent to all the other parts of the system to work properly.

Hydraulic Pump:

- The hydraulic pump is generally used to pump the fluid from one place to another place whereas here in this unit, it acts as a mediator between the reservoir and the Intensifier.

- It sucks the water from the reservoir and sends it to the Intensifier.

Hydraulic Intensifier:

- It is connected after the hydraulic pump and is used to increase the pressure of the water.

Accumulator:

- The accumulator is used to store the water temporarily and supplies the water in the system when there is either a pressure drop or high-pressure water required in the system.

Control Valves:

- The duty of the pressure control valve is to control the pressure of water and also the direction of water.

- A flow regulator valve is used to regulate the flow of water into the system.

Flow regulator:

- As the name flow regulator, it is used to regulate the flow of water which was arrived from the control valve and send that water towards the nozzle.

Abrasive Tank:

- Abrasive particles play a vital role in this process. As we know that water jet machining process is used to cut soft materials whereas, in order to cut the hard materials, just water is not sufficient.

- In addition to water, Abrasives are also added so that the material can cut at a faster rate. The commonly used Abrasive particles are aluminum oxides, sand, garnet, glass particles, etc.

Mixing Chamber:

- In the water jet machining process, only water is used as a cutting medium whereas, in the Abrasive Water Jet Machining process, 70% water and 30% Abrasive particles are used and they are mixed in the mixing chamber.

Nozzle:

- The duty of the nozzle is to convert high-pressure water into kinetic energy(K.E) and this K.E. is increased due to the decrease in the nozzle area. This high K.E. water along with the abrasive particles is impinged onto the surface of the workpiece to get the desired shape and size at a faster rate.

Drain system:

- The main duty of the drain is to collect the water coming away from the work region and is supplied back to the reservoir via the pump and the filter.

Process Parameter :

- Cutting speed can be high as 7.5 m/min for reinforced plastics, but much lower for metals consequently.

- The most common usage of abrasive particles in the AWJM process is in the range of 100 to 150 grit.

- The most used abrasive materials are Garnet(which is 30% more efficient than sand), Silicon Carbide and Silica.

- The depth of cut decreases when the traverse rate is increased. The Traverse speed maintained is 100 mm/min to 5 m/min.

- The depth of cut maintained is in the range of 1 mm-250 mm.

- If the stand-off distance is increased, the depth of the cut is decreased. The stand-off distance maintained is 1-2mm.

- Abrasive Water Jet Machining (AWJM) is used to cut much harder materials and metals.

- With multiple axis and robotics control machines complex three dimensional parts can be machined to finish dimensions.

Working of Abrasive Water Jet Machining(AWJM) :

- The water from the reservoir is to be passed to all the parts of the system starting from the reservoir to the drain system. Firstly, the water is passed through the hydraulic intensifier where the pressure of the water increases and is to be sent to the accumulator for storing the water on a temporary basis.

- The control valves are placed in the system to control the pressure of water and the directional flow of water. Next, the abrasive particles along with water in a percentage of 30 & 70 are mixed in the mixing chamber.

- When these high-velocity Abrasive particles are impinging onto the hard workpieces, it is possible to produce plastic deformation fracturing in the hard work materials.

- As the percentage of abrasives is increasing, the material removal also increases but the flow characteristics of the liquid mixture are coming down.

- Therefore, the optimum percentage of abrasives will be about 40 to 60%.

- It is mainly developed for cutting granite and marble of complex shapes.

Advantage of AWJM :

- No heat-affected zone

- No cutter induced distortion

- Eliminates thermal distortion

- Low cutting forces on workpieces

- Localises structural changes

- No slag or cutting dross

- Limited tooling requirements

- Typical finish 125-250 microns

Disadvantage of AWJM :

- High capital cost.

- High noise levels during machining.

- It cannot cut the materials that degrade quickly with moisture

Application of AWJM :

Application of Abrasive Water Jet Machining(AWJM) are as follows :

- It is highly used in the automotive, aerospace, and electronics industries.

- In aerospace industries, parts such as engine components (aluminum, titanium, and heat resistant alloys), aluminum body parts, titanium bodies for military aircraft, etc. are made using abrasive water jet machining process.

- Laser Beam Machining(LBM)

- Automation And Types of Automation in Manufacturing

- Numerical Control(NC) and Computer Numerical Control(CNC)

- Plasma Arc Machining(PAM)

- Heat Engine, Classification of Heat Engine and Its Component

daxktilogibigibi.veFDLhWgQx3m

xyandanxvurulmus.wGY12R0reWYN

xbunedirloooo.K827RPFM6szn

shapeup xyandanxvurulmus.KhEhz0zw8oSd

asthore xyandanxvurulmus.zdWKKPX6WqIg

78betinnova, huh? Sounds fresh! Thinking of giving them a spin. Anyone had any luck over there? Spill the tea! 😉 78betinnova

Ki888, eh? Keen to jump in and try my luck. Fingers crossed for some big wins! Giving it a go now. Find out more here ki888

Heard about jilicrown22 from a buddy. It’s not the flashiest site, but it’s reliable. Good for low-stakes fun, might want to look elsewhere if you want to gamble big.

Dola789link – Seems like a decent spot to try your luck. Games load fast which is a plus in my book. Good selection too. Check ’em out! dola789link

AU88AMSL, checking it out! Honestly, the signup bonus caught my eye. Let’s see if it’s as good as it sounds. Wish me luck, y’all! Time to try and win some! au88amsl

Okay so I’ve used okvip okvipo.com before. The thing that really stuck out was the support. Try it out and see what you think –> okvip okvipo.com

Yo, anyone got the inside scoop on win777affiliate? Thinking of checking it out. Any feedback is appreciated. win777affiliate

Hey all! Heard good things about 888wincasino. Anyone else playing there? What’s the vibe? Gotta try and win something cool. 888wincasino

Hey guys, stumbled upon Tigrinhoonline the other day. Not gonna lie, its kinda fun! If you like fast-paced games, give it a go. Check it out tigrinhoonline

Heard about usbetvn from a buddy. Gave it a try and gotta say, it’s legit. The interface is easy to navigate makes placing bets simple. You should check it out usbetvn

Yo, vn138 crew! Been hanging out on this site for a while. It’s got a good vibe and plenty of options. Definitely worth checking out when you wanting some action! Jump in to vn138