Abrasive Jet Machining (AJM)

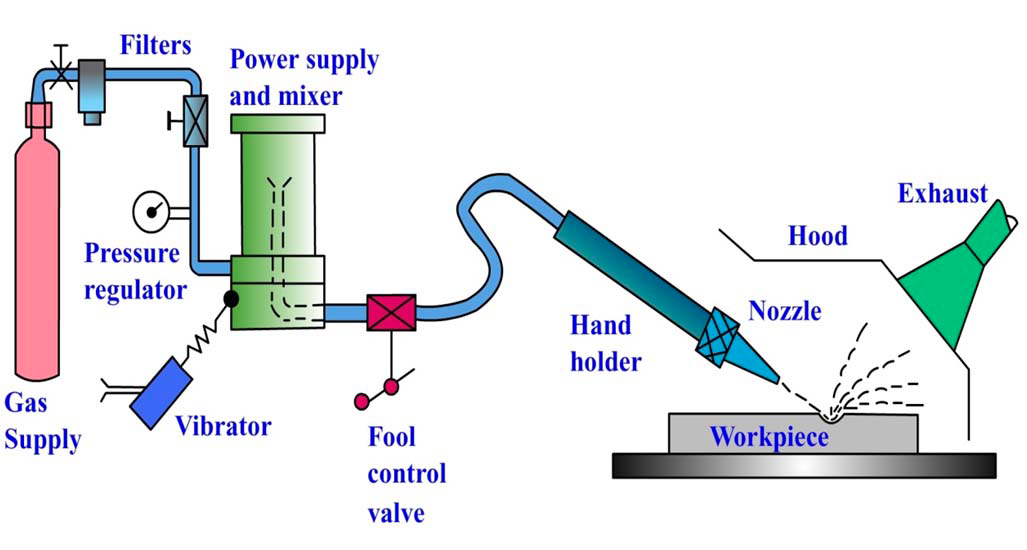

The fundamental principle of Abrasive Jet Machining involves the use of high speed stream of abrasive particles carried by a high presssure gas or air on the work surface through a nozzle.

The metal removal occurs due to erosion caused by abrasive particles impacting the work surface at high speed with repeated impacts, small bit of material on the workpiece got loosened and a fresh surface is exposed to the jet.

The filtered gas supplied under a pressure of order of 850KPa to the mixing of chamber containing the abrasive powder and vibrating at 50Hz.

This abrasive gas mixture emerge from a small nozzle mounted on a fixture at high velocity ranging from 150 to 300m/min. The carrier gas should be non-toxic, cheap and easily available.

Air or Nitrogen are generally used gas in the Abrasive Jet Machining.

The abrasives generally employed are Aluminium Oxide or Silicon Carbide.

Since the nozzle are subjected to a great degree of abrasives wear, they are made of materials such as Tungsten Carbide or Synthetic Sapphire to reduce the wear rate.

The metal removal rate depends upon the diameter of nozzle, composition of abrasive gas mixture, jet pressure, hardness of abrasive particles and that of work material, particle sixe, velocity of jet and ditance of workpiece from the jet.

Advantage of AJM :

- It can be used in any material, conductive, non-conductive or brittle.

- Good dimensional accuracy.

- Good surface finish.

- Due to negligible force delictae workpiece can be machined.

Disadvantage of AJM :

- Dust control needed.

- Low Material Removal Rate.

- Embedding of abrasives particle in soft worpiece.

Application of AJM :

- Cutting and drilling on metal foils and thin sections of ceramic and glass.

- Machining brittke and sensitive materials like quartz, sapphire, ceramics, etc.

- Intricate holes in electronic components such as resistor paths in insulation.

- Cleaning hard substance deburring, polishing, etc.

- It is used for producing the high quality surface.

daxktilogibigibi.T13B3ElG6PSU

xyandanxvurulmus.QRm7RXmukx3b

xbunedirloooo.HfVhbZdL0x1c

attitudinally xyandanxvurulmus.UrNR1RsCSVPo

rockslides xyandanxvurulmus.6efBHWGkOb6N

escort wrtgdfgdfgdqq.7th4TPjKLEZE

fuck google wrtgdfgdfgdqq.pHB36Pfj9oKJ

Heard 678win has some great offers. Might have to try deposit some money. Good service always makes gaming fun. 678win is worth a try!

Alright listen up, mmabetr is the real deal. Found some sweet odds there and had a decent run. Give mmabetr a look, you might just find your new favorite thing. Check out mmabetr.